AIR LINE CONTROL

Legris Tubing:

Nylon,Polyethylene, Polyurethane

Standard Sizes - 1/8" to 1/2"

Metric Sizes - 4 to 16

Nylon,Polyethylene, Polyurethane

Standard Sizes - 1/8" to 1/2"

Metric Sizes - 4 to 16

Legris Fittings:

Nylon, Nickel - Plated Brass,

Stainless Steel

Push - To - Connect

Standard Size - 5/32" to 1/2"

Metric Size - 4 to 12

Nylon, Nickel - Plated Brass,

Stainless Steel

Push - To - Connect

Standard Size - 5/32" to 1/2"

Metric Size - 4 to 12

Lubricators:

Parker and Wilkerson

1/4" to 3/4"

Parker and Wilkerson

1/4" to 3/4"

Filters:

Parker and Wilkerson

1/4" to 1"

Parker and Wilkerson

1/4" to 1"

Regulators:

Parker and Wilkerson

1/4" to 1"

Parker and Wilkerson

1/4" to 1"

N32-W1-DPI

Differential pressure indicator used on most models 1/4" through 2" NPT

Differential pressure indicator used on most models 1/4" through 2" NPT

ELIMINIZER

REPLACEMENT ELEMENTS

N32-95-020

Blanking cap used to replace indicators

Blanking cap used to replace indicators

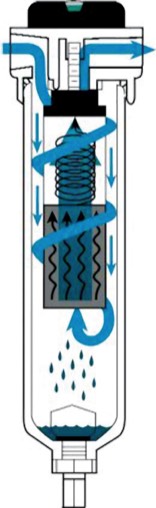

Centrifugal Spinning

Bulk contamination water, dirt, and oil enter and are spun in a circular manner as the air flows vertically downward. This spinning action, which is naturally created by RTi’s patented element design, forces heavy particles outward where they contact the inside of the bowl and drain to the sump area.

Inverse-Flow

RTi’s patented Inverse-Flow process creates a condition where the air, which is spinning rapidly as it flows vertically downward, changes direction 180 degrees and begins to flow vertically upward. This process prevents the re-entrainment of contamination which normally occurs. Contamination, which is flowing vertically downward, is not capable of reversing direction and must separate from the air flow, falling to the sump area at the bottom of the bowl. This separation effectively pre-filters the air of bulk contaminants, thereby extending the life of the RTi filter element.

Stainless Steel Media: Filteration to 3 Micron

The first filter media which the pre-cleaned air enters is a deep bed of finely interwoven stainless steel mesh wires. These wires have an extremely striated outer surface and will hold small aerosols and liquid droplets which have survived the Inverse-Flow mechanical separation and centrifugal spinning processes. These small droplets will collect on the wire media, forming larger droplets which will fall into the drain area.

Friction Drying & Filtered Air To 1 Micron

Consisting of a cotton and polyester blend interwoven with stainless steel material, the final filter media captures sub-micron water droplets which have passed through the stainless steel wire mesh and delivers filtered air to 1 micron. Cotton holds submicron water particles and allows them to re-enter the airstream as a harmless vapor.

Rugged Bowl Assembly

The RTi Eliminizer® features polycarbonate bowls with bowl guards as well as, powder coated metal bowls and high-pressure, high-temperature, food grade, and 316 stainless steel options.

One: Dry, Oil-Free Air

RTi’s exclusive, patented Inverse-Flow process delivers 100% removal of oil and water liquid contaminants, plus oil vapor removal to 0.003 ppm! A filter change/DP indicator is inlcuded.

Stage Two: Long-Life Desiccant Media

RTi’s exclusive pre-filter dramatically extends desiccant efficiency for longer cartridge life. Replacing the desiccant media is simple, and removing the patented spin-off, spin-on element takes only seconds. The desiccant cartridge also features a coalescing final filter for 1 micron dust removal.

Unique Dew-Point Indicator Eliminates Guesswork

RTi’s exclusive dew-point indicator lets you know when the desiccant cartridge needs to be replaced. When the color changes to pink, you know the desiccant media needs to be replaced.

Attention To Detail - Inlet Shut-Off Valve And Snaplock Regulator

Every RTi Eliminator® II ships with an inlet shut-off valve and a snap-locking regulator for easy servicing and precise air pressure settings that lock in place with finger-tip control.

Automatic Drain

The first-stage unit includes a reliable automatic float drain to remove liquids that build up in the bowl. Our exclusive manual override feature is standard on all E4000 and N4000 float drains.

Heavy Duty Construction

Designed for safety and durability, including: solid metal bowls, automatic drains, stainless steel components, inlet shut-off valve, regulator and 0-160 psi gauge with precision snap-lock feature for hassle-free pressure setting, and mounting brackets.

DRYERS AND COOLERS

Electronic Drain

Advantages:

Equipped with Straining Ball Valve Standard, Manual Adjustment for purge & cycle duration, 6’ Electrical cord

Advantages:

Equipped with Straining Ball Valve Standard, Manual Adjustment for purge & cycle duration, 6’ Electrical cord

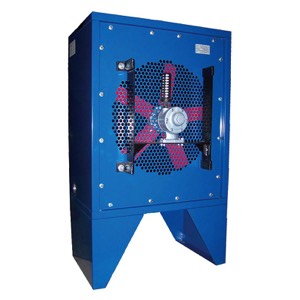

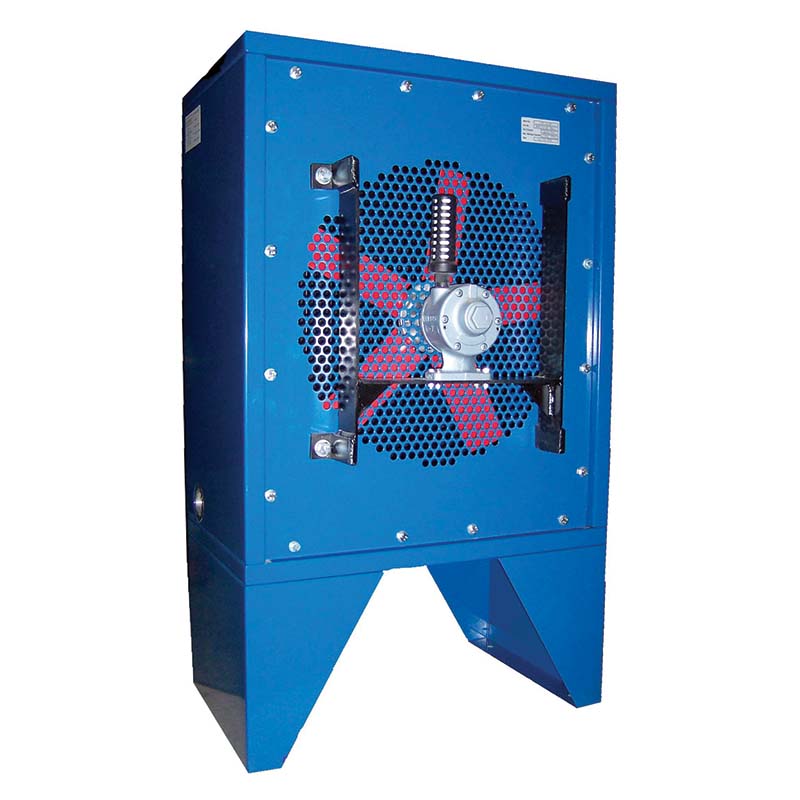

Aftercoolers:

Models: PA35 - PA1800

Optimizes Air for Use Removes Moisture, Lubricants and Particles, Reduces Maintenance Throughout the System, Versatile, Affordable and Easy to Install, Heavy Duty Construction

Models: PA35 - PA1800

Optimizes Air for Use Removes Moisture, Lubricants and Particles, Reduces Maintenance Throughout the System, Versatile, Affordable and Easy to Install, Heavy Duty Construction

Heatless Twin Towers:

Models: PH20A - PH1630A

Maximum Performance and Reliability, Long Service Life, Virtually Maintenance-Free Operation, Standardized Components, Low Bed Velocities and Optimum Flow Path, Economical and Efficient

Models: PH20A - PH1630A

Maximum Performance and Reliability, Long Service Life, Virtually Maintenance-Free Operation, Standardized Components, Low Bed Velocities and Optimum Flow Path, Economical and Efficient

Refrigerated Dryers:

Models: PRA10A - PRW1750A

Insulated Heat Exchanger, Automatic Drain Trap Galvanized Steel Cabinets, Low Pressure Drop for High Efficiency, Oversized Condenser for Industrial Conditions, Environment Friendly

Models: PRA10A - PRW1750A

Insulated Heat Exchanger, Automatic Drain Trap Galvanized Steel Cabinets, Low Pressure Drop for High Efficiency, Oversized Condenser for Industrial Conditions, Environment Friendly

ACCESSORY VALVES

Quick exhaust valves provide rapid exhaust of control air when placed bewteen control valve and actuator.They can also be used as shuttle valves.

Legris Quick Exhaust Valve

Sizes 1/8" thru 1/2"

Sizes 1/8" thru 1/2"

Parker Quick Exhaust Valve

Sizes 1/8" thru 3/4"

Sizes 1/8" thru 3/4"

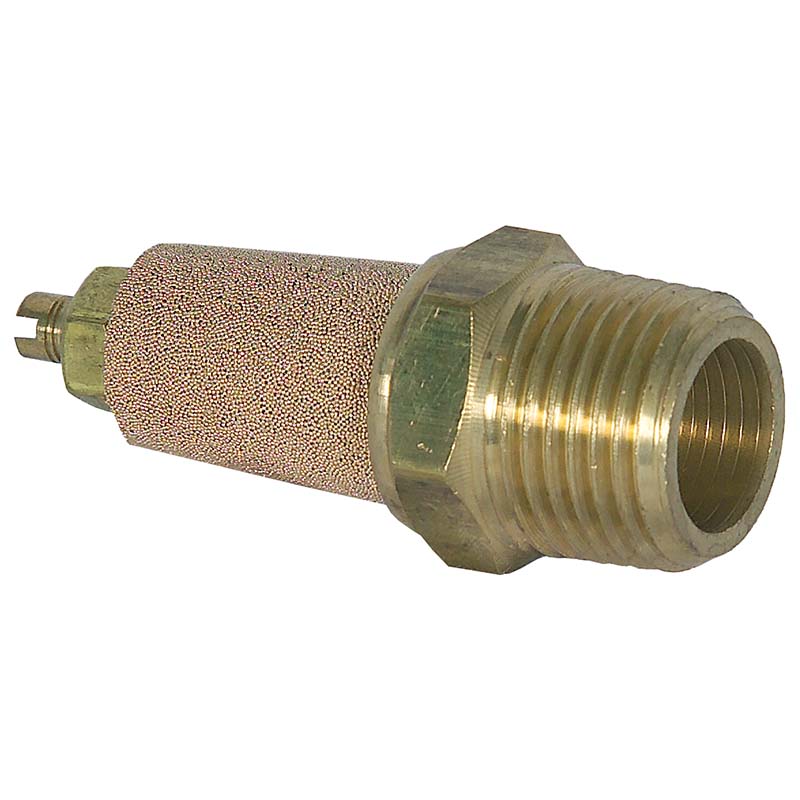

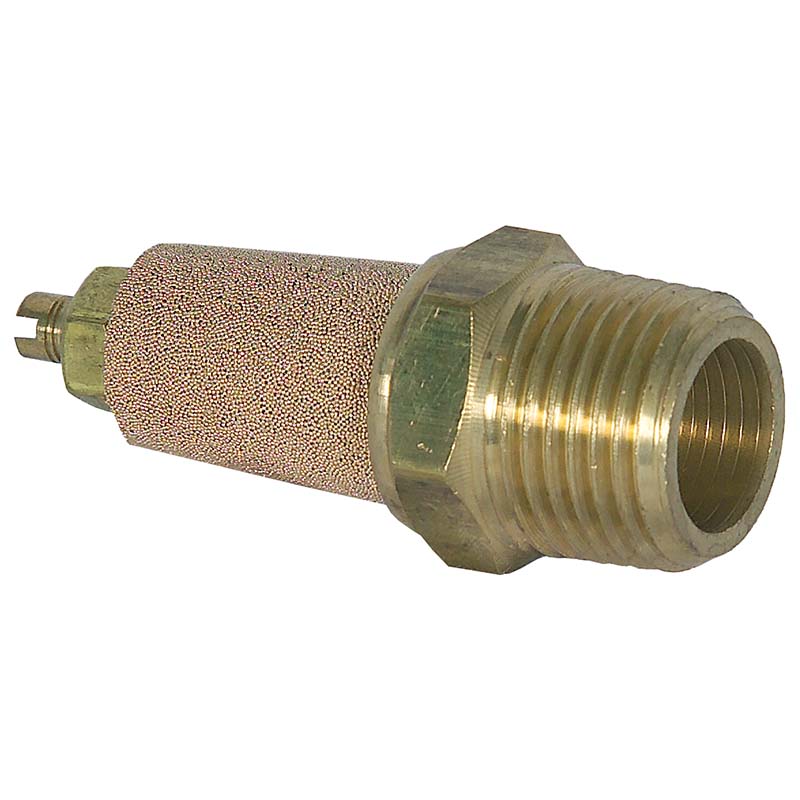

EXHAUST MUFFLERS

Exhaust Mufflers and speed Control Mufflers

Sizes 1/8" thru 1-1/2"

Sizes 1/8" thru 1-1/2"

Exhaust Mufflers and speed Control Mufflers

Sizes 1/8" thru 1-1/2"

Sizes 1/8" thru 1-1/2"

Aeration & Blowers • Air Line Control • Boots • Cement Screws & Loading Spouts • Concrete Plants • Conveyors • Dust Control System • Level Controls • Mixers • Valves & Cylinders • Vibrators • Water & Moisture Meters & Pumps • Wear Liners

C & G Equipment ● 3590 NW 96th Ave. ● Hollywood, FL 33024 ● Phone: (954) 602-1265 ● Fax: (954) 602-1275