CONVEYORS

Representing Precision Pulley & Idler Conveyor Products who has been providing belt conveyor idlers for 40 years. We at C & G Equipment provide only the highest quality components in the conveying industry while our customers need involvement, responsiveness, credibility and follow-through. Our goal is to offer our customers more than just the best products and service but a level of professionalism beyond our customer’s expectations.

PPI Retro Rolls allow you to use our proven idler rolls in other manufacturer's frames.

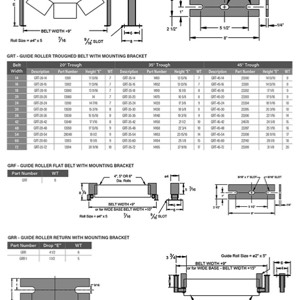

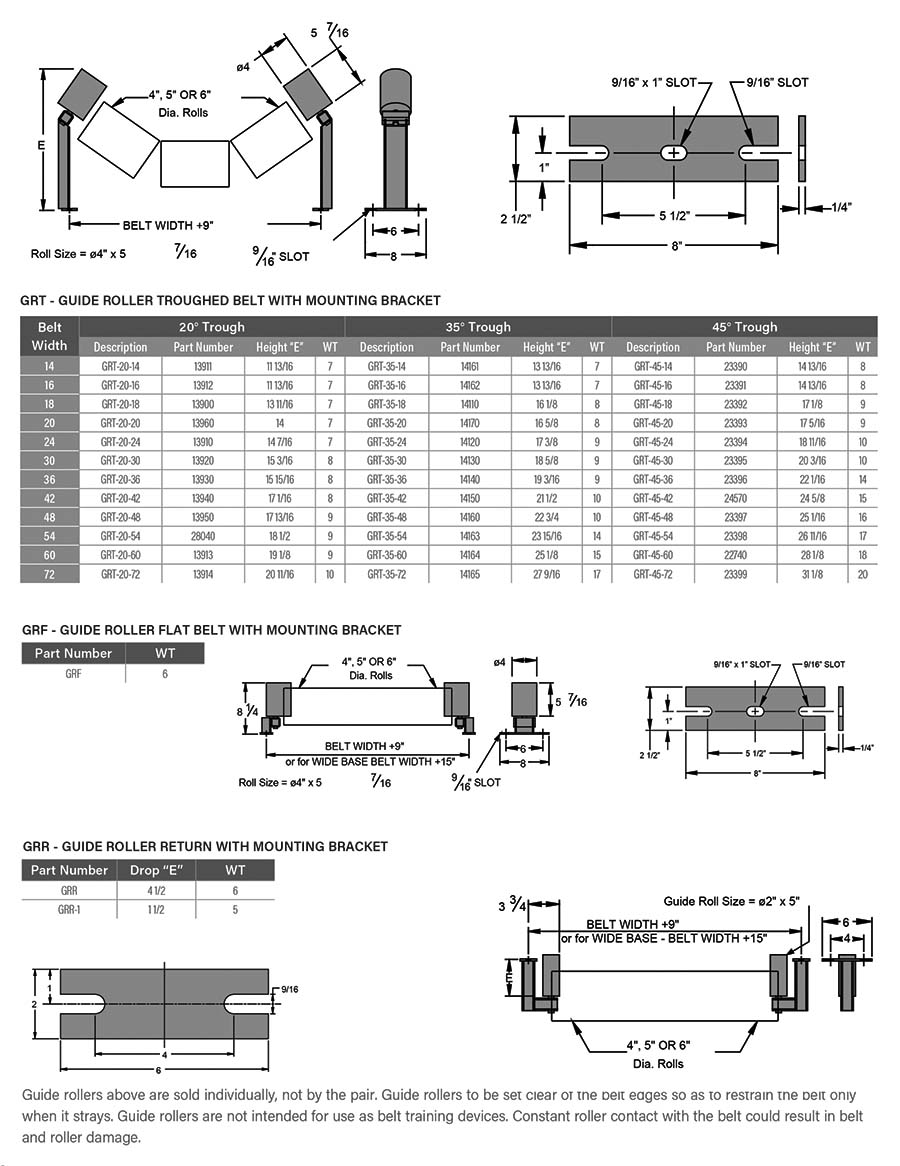

C & G supplies a 2-1/2" Dia. X 6-7/16" Long Urethane Guide Roller with a 3/4" Shaft Dia.

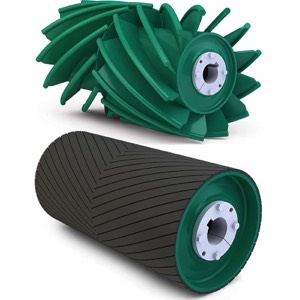

PPI’s Pro Trainer was designed to actively train a conveyor belt while operating on the clean side of the belt. Training a belt on the clean side offers significant advantages compared to traditional return self aligners by eliminating the potential of material carry back building up on the roll negating the training characteristics. Clean side training combined with guide rolls positioned in such a way that minimizes belt misalignment before engaging the lagged training roll, provides unmatched belt alignment.

RETURN ROLLER GUARDS

Guide Rollers

Click on the image to enlarge.

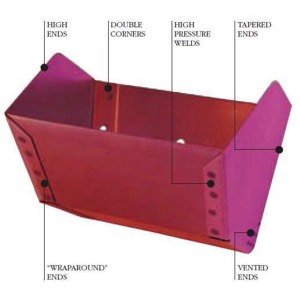

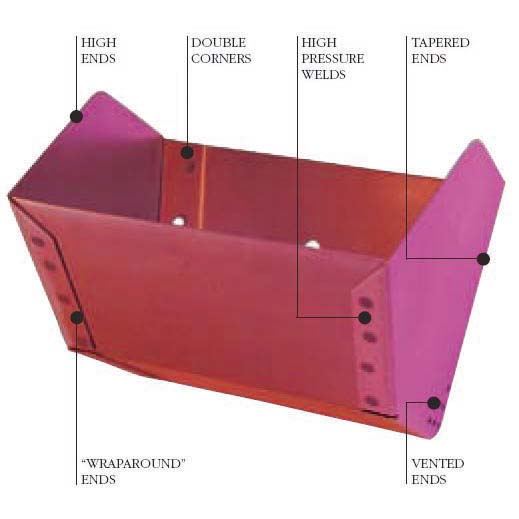

Return Roll Guards

The PPI Return Roll Guard provides a barricade at the pinch point created by the belt passing over a return roll. The 1 1/2” or 4 1/2” mounting brackets provide easy installation on 4”, 5” or 6” rolls utilizing the return bracket’s mounting bolts. While normally used on return rolls with seven feet or less vertical clearance from the ground or decking, it may be used on any return roll.

Douglas Guardian 3

The patented Guardian3 is the best tool on the market to enhance the safety of your conveyor. Accept no substitutes and cut no corners when it comes to the safety and well being of your most important assets... your people. Trust the Guardian3.

Guard Panels

Guard Panels are a simple to install safety solution. You can keep rolls of our Guard Panels in stock at your site to quickly fulfill MSHA determined requirements. The yellow, UV resistant material we use for our Guard Panels can be easily cut and trimmed to fit the areas that you need covered. Our 100×4 foot side guard rolls come in ¼ inch mesh and our 50×4 foot bottom Guard Panels come in ¾ inch mesh. We make installation of our Guard Panels even easier by including self-tapping screws and washers, shipping the all-in-one package to you ready to be fitted on your machinery.

CONVEYOR BELT SUPPORT SYSTEMS

FEATURES AND BENEFITS

• Simple, cost effective way to provide continuous support of your conveyor belt against the skirting material

• Ultra-high-molecular-weight (UHMW) slider rails for skirt board sealing

• No moving parts

• Seals skirt boards in loading zone to reduce spillage

• Supports conveyor belt in loading zone

• C-Channel frames for increased strength

• Fold-down wings for ease of maintenance

• Modular design allows multiple units to be fitted end-to-end to form the length needed

• Match center-roll height of CEMA C and D idlers • Available in belt widths from 18” through 72”

2’ Impact Bed

5’ Impact Bed

4’ Impact Bed

BELT CONVEYOR HOODS

Standard style "A-1" belt conveyor hoods consist of cover sections supported on bands spaced at 4' - 0" centers.

• Galvanized from stock in 18" through 48" belt sizes

• Optional aluminum construction

• Quick opening

• Easily installed

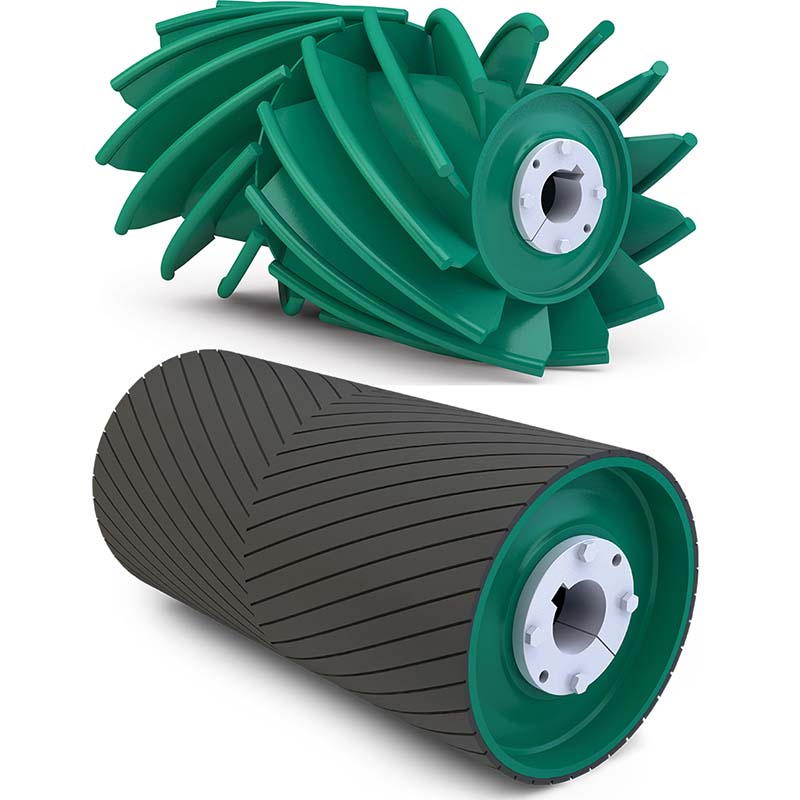

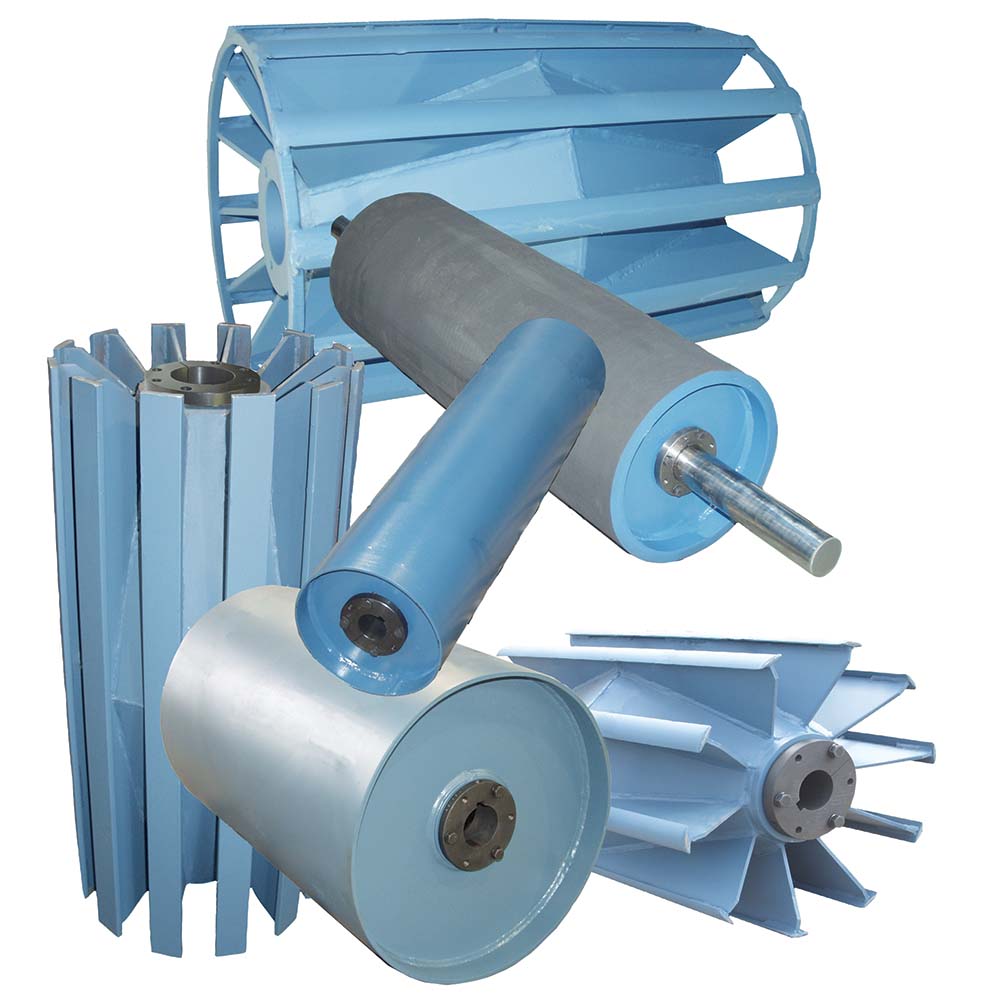

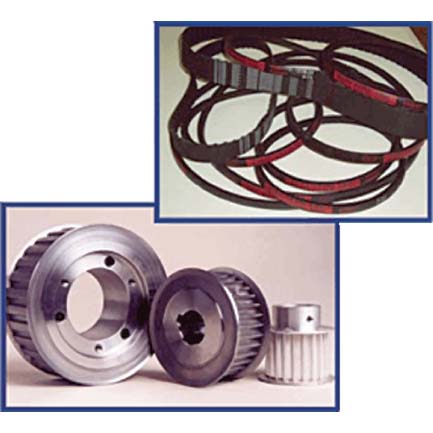

PULLEYS

Our Pulleys are manufactured by America Pulley & PPI and all products meet or exceed Conveyor Equipment Manufactures Association standards C (Cema) for Bulk Material Handling. The methods of manufacture are modern and each pulley is checked for quality. End disc and Rim thickness are selected and pre engineered by computer generated program. Often times our pulleys will employ additional center disc, ring stiffeners, or increased bushing sizes etc.

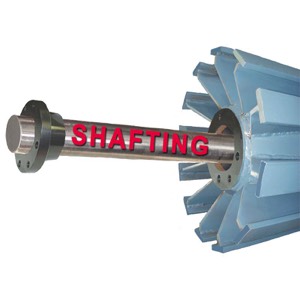

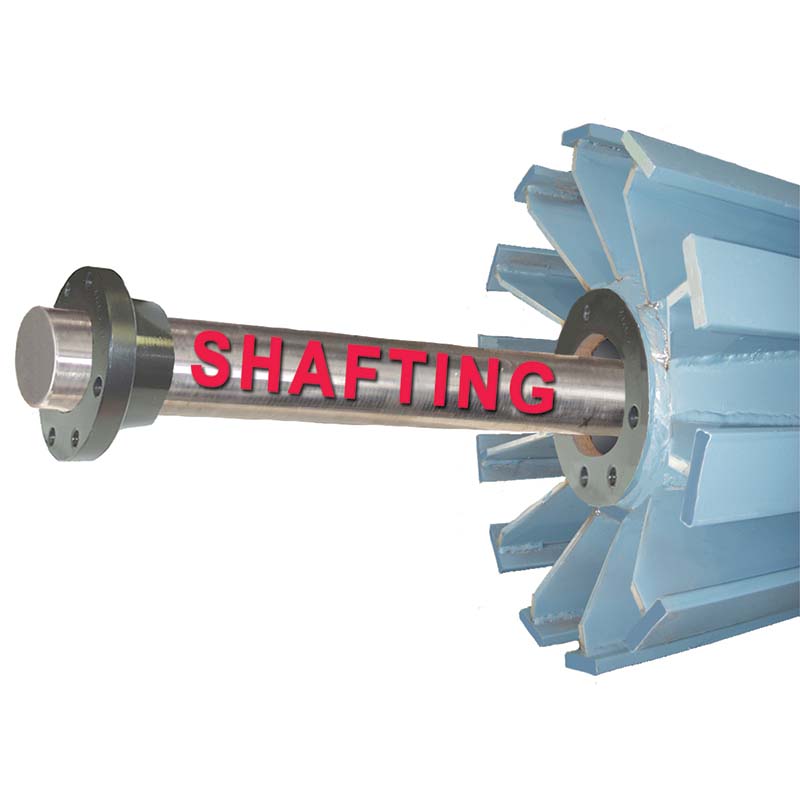

SHAFTING

American Pulley & PPI manufactures shafts for pulley assemblies. All shafting is 1045 steel for minimum deflection and strength. Keyways are cut under bushings where required and factory assembled to insure quality and compatibility. Alloy and special shafts will be supplied as required.

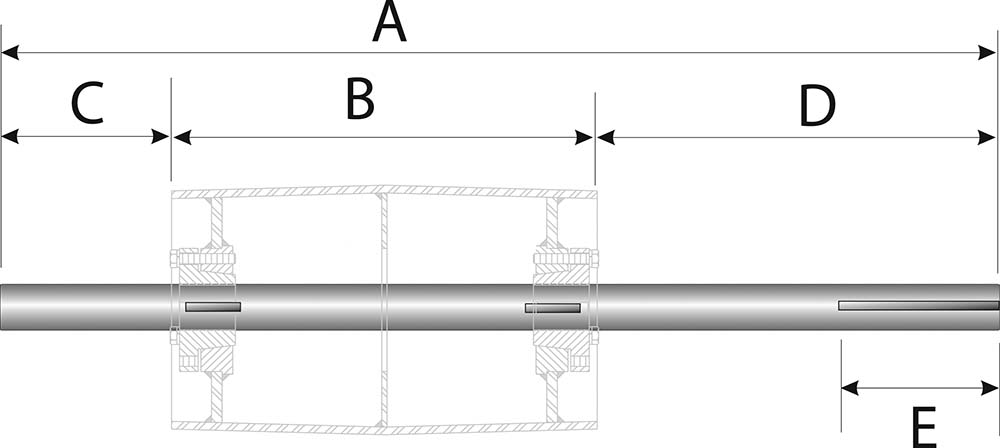

A- Overall Length B- Pulley Length C- Length from Pulley to Shaft End

D- Length from Pulley to Drive End E- Keyway Size and Length

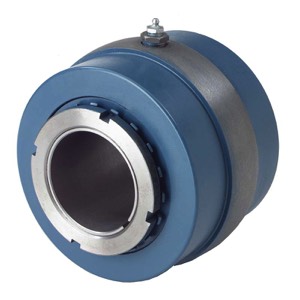

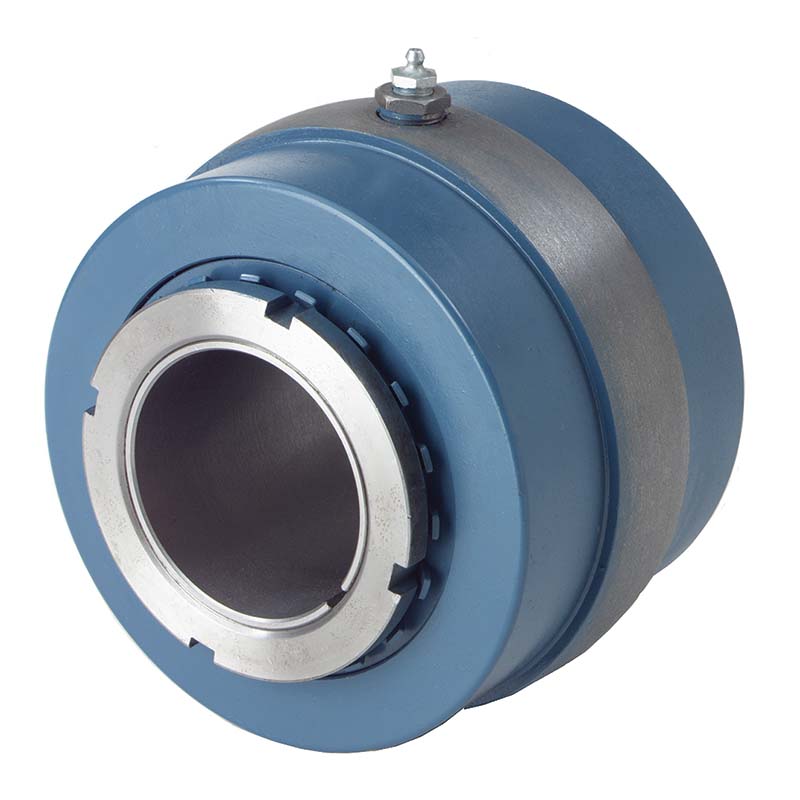

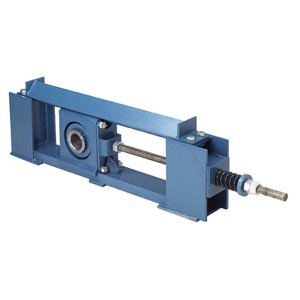

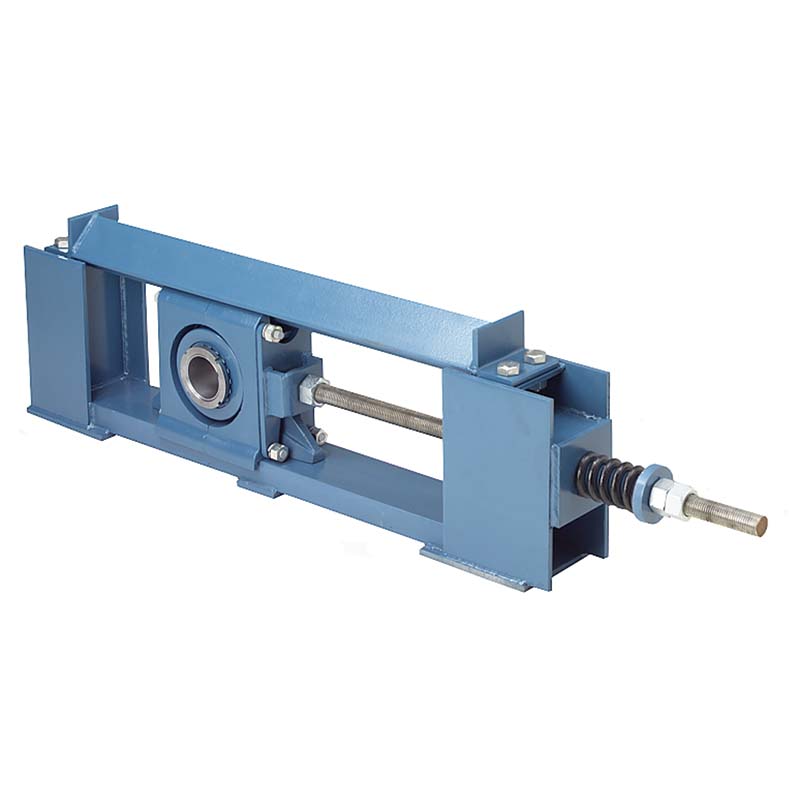

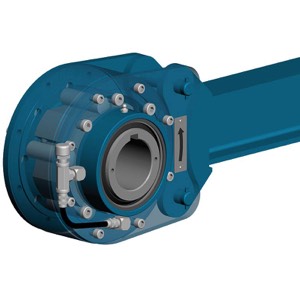

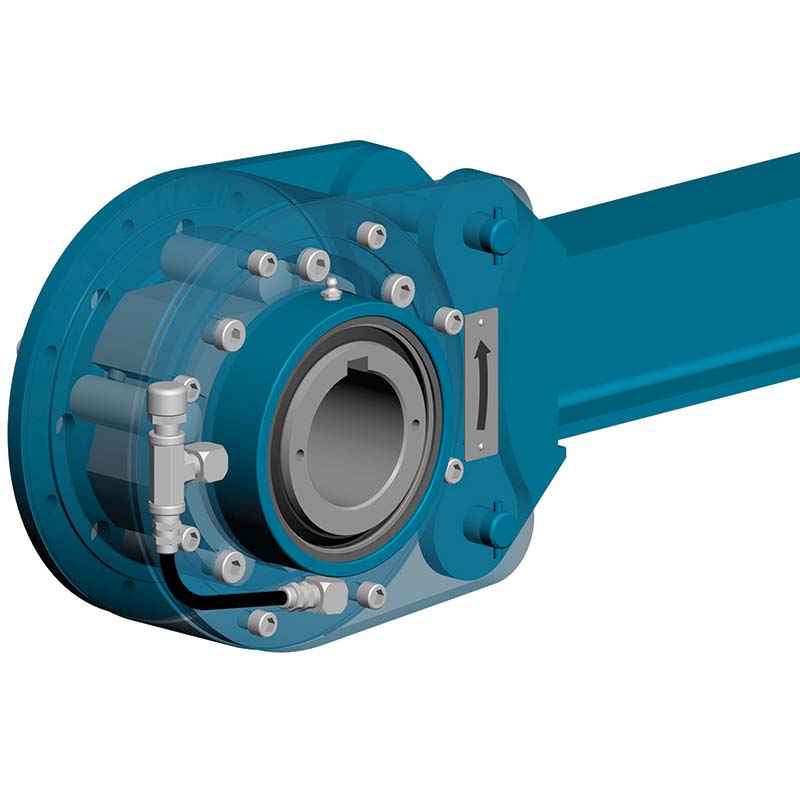

BEARINGS & TAKEUPS

Jones is a full-line manufacturer of mounted spherical roller bearings and standard and heavy duty takeups.

• High Quality USA Made Spherical Roller Bearings • Internal Misalignment • Triple Labyrinth Seal

• Collar Mounted • Interchanges with Most Major Brands

Normal Duty Takeups • Protected Screw Takeups • Center Pull Takeups • Extra heavy Duty Takeups • Pillow Block Takeups

BELTING

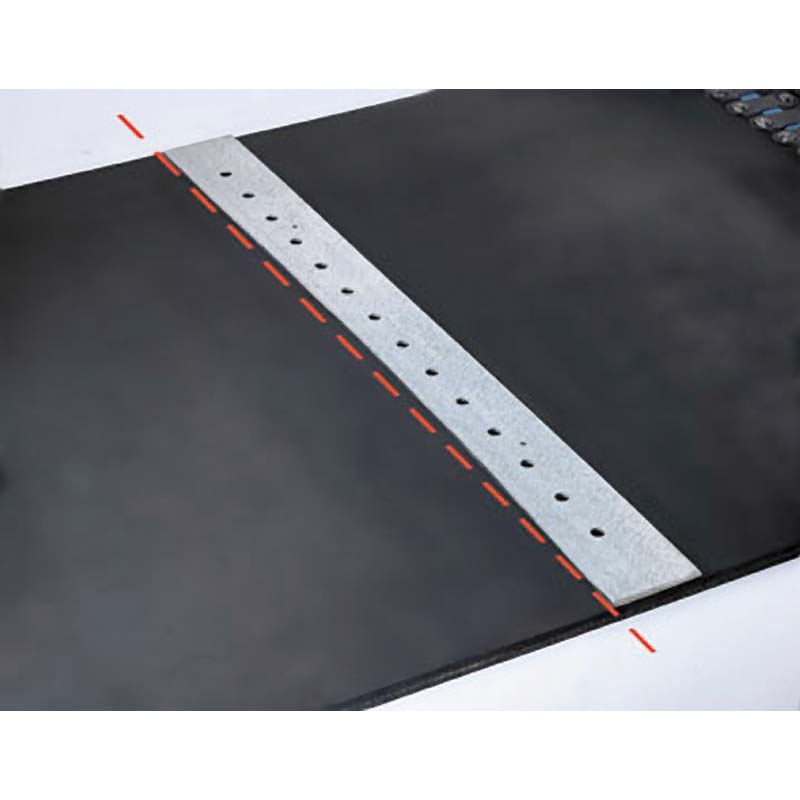

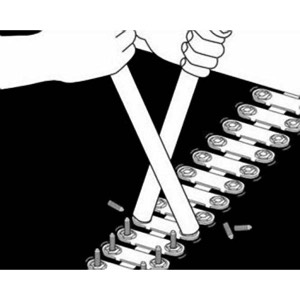

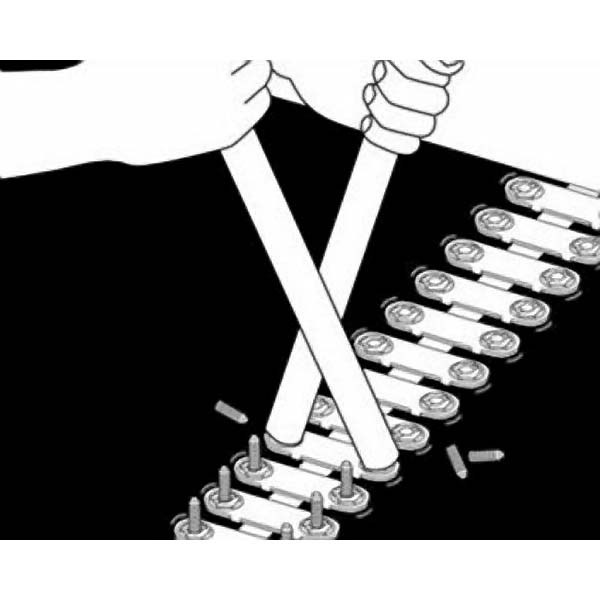

Flexico - Belt Fasteners & Accessories

We can supply all Flexco belt fasteners and tooling.

BELT WIPER SYSTEMS

Primary Wiper Systems

Argonics' conveyor belt scrapers provide unrivaled cleaning power and durability.

• For low-clearance areas

• For conveyor belts running at 400 fpm or less

• Works best on belts up to 48" wide with head pulley diameters of 28" or less

• Available with Safe Torque™ ratchet system

• 3/16" thick, 2"×2" heavy-duty mainframe

• Galvanized schedule 80 stub ends

• Single-pin, quick-change blade mount

• Perma-Torque™ tensioner

• Standard industrial cleaning system

• For belts running at 500 fpm or less

• Can be used in a Dual Primary setup, giving you twice the cleaning power

• Safe Torque™ ratchet system comes standard

• ¼" thick, 3"×3" heavy-duty mainframe

• Galvanized schedule 80 stub ends

• Single-pin, quick-change blade mount

• Perma-Torque™ tensioner

• Uses multiple 6" wide × 8" tall

--Raptor blades

• Has a reinforced mainframe and heavy-duty channel attachment design

• Slide blade mount with galvanized holders

• Safe Torque™ ratchet system comes standard

• ¼" thick, 3"×3" heavy-duty mainframe

• Galvanized schedule 80 stub ends

• Single-pin, quick-change blade mount

• Perma-Torque™ tensioner

• Mine duty cleaner with a ¼" thick, 3½"×3½" box steel mainframe

• Built for high-speed, high tonnage belts

• Galvanized schedule 160 stub ends

• Single-pin, quick-change blade mount

• Safe Torque™ ratchet system comes standard

• Perma-Torque™ tensioner

• Designed to combat crowned head pulleys with heavy vibration in harsh environments

• Mine-duty, channel-mount version of the Super Eraser

• Galvanized schedule 160 stub ends

• Slide blade mount with galvanized holders

• Safe Torque™ ratchet system comes standard

• Perma-Torque™ tensioner

• Economical yet designed for performance and reliability

• Effective cleaning performance with a 6” (152 mm) tall polyurethane blade

• Easy to install and tension and requires little to no maintenance.

• Offers a simple and effective spring tensioning unit – keeping consistent pressure against the conveyor belt

• Single pin blade attachment means quick and simple blade change out with less downtime

Secondary Wiper Systems

Argonics' conveyor belt scrapers provide unrivaled cleaning power and durability.

• Unique pass-through mainframe allows material to fall through freely

• Available with polyurethane or tungsten carbide blade

• Based on the same heavy-duty mainframe as the Eraser system

• Galvanized schedule 80 stub ends

• Single-pin, quick-change blade mount

• Safe Torque™ ratchet system comes standard

• ¼" thick, 3"×3" heavy-duty mainframe

• Perma-Torque tensioner

• Polyurethane, tool steel, stainless steel or tungsten carbide blades available

• Web Torque™ tensioner

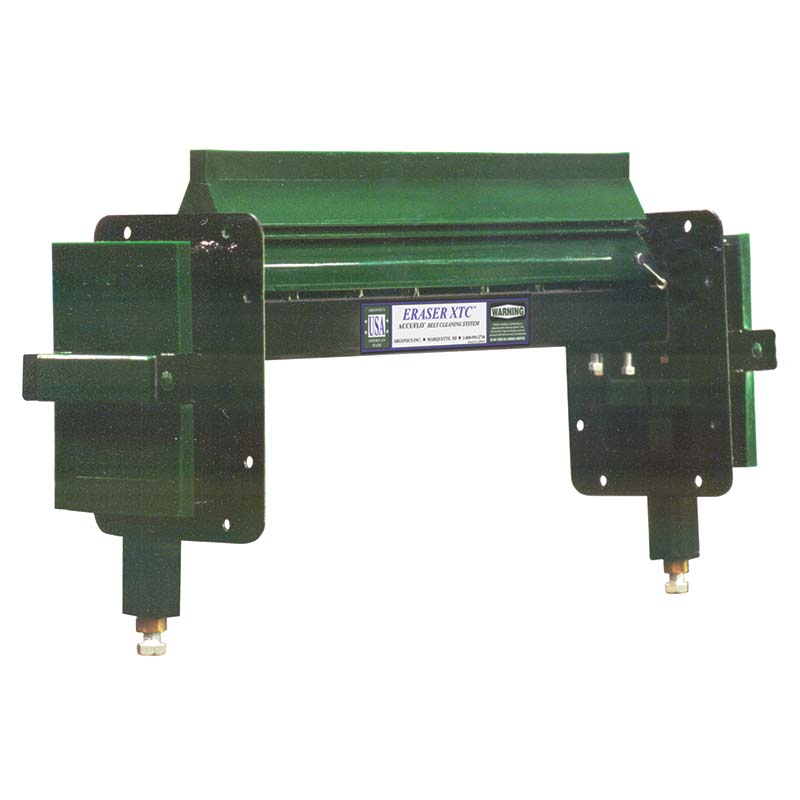

Tertiary Wiper Systems

Argonics' conveyor belt scrapers provide unrivaled cleaning power and durability.

• Designed to meet demands of largest quarry plants

• Scalps the belt clean with adjustable downforce

• Extra heavy duty nose cone blade

• Comes with safety chains and nose cone support

• ¼" thick, 2½"×2½" heavy-duty frame

• Vanadium die spring tensioners

• Adjustable down pressure system

• Comes with safety chains

• Telescoping stub ends allow for easy mounting

• ¼" thick, 2½"×2½" heavy-duty frame

• Vanadium die spring tensioners

• Economical solution for budget-conscious who want protection of a V-Plow

• Chains and nose cone support are optional

• Extra heavy duty nose cone blade

• C3X5 channel steel mounting brackets

• ¼" thick, 2"×2" heavy-duty frame

• Locking collars

Argonics belt wipers are available in the standard pin style adjustment and the new Safe Torque. The Safe Torque system is a unique solid urethane ratchet adjustment device, specifically designed to work in conjunction with our patented Perma-Torque tensioning system.

The Safe Torque ratchet system offers the unique ability to tension a conveyor belt cleaning system with one hand, and is extremely useful in confined areas. The dust caps seals the system from fine particle contamination, common to many tensioners on the market.

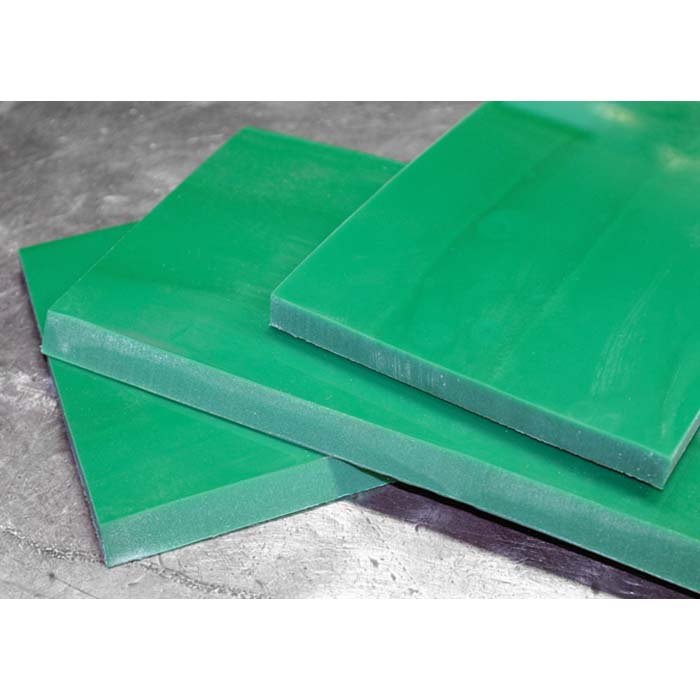

• Designed to outlast your original equipment blades by meeting or exceeding the original manufacturer's cleaning and wear requirements

• Retrofit a majority of the conveyor belt cleaners on the market today

• Made of high performance Kryptane polyurethane

• Heavy duty aluminum inserts

• Multiple formulations

• MSHA and FDA food grade formulations available

• Some secondary blades are available with tungsten carbide tips

SKIRTING PRODUCTS

• Extremely resilient, outlasting rubber and UHMW polyethylene

• Available in 4", 5", 6", 8", 9", 10" and 12" widths with thicknesses

ranging from 3/8" to 2", and lengths up to 50'

• Available with straight or 20°, 35° and 45° beveled edges

• 8 to 10 times the wear life over quality rubber skirting

• MSHA-accepted, flame-retardant formulas available

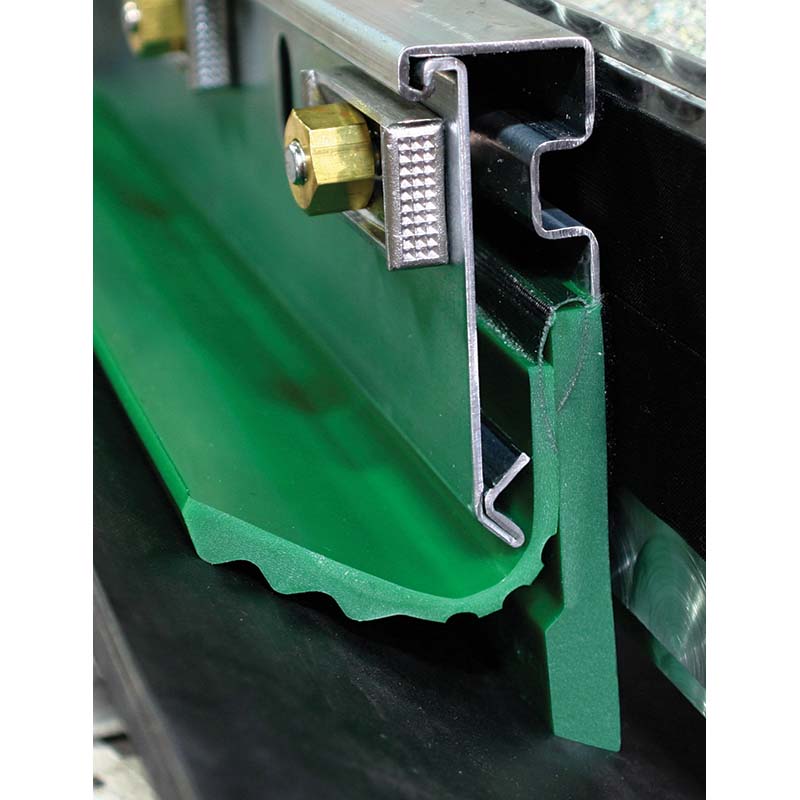

• Quickest adjustment of any skirting system in the industry

• Comes standard with Argonics' ½"x5" beveled green polyurethane skirting

• Solid galvanized 12 ga steel mounting rail

• Accepts skirting thicknesses from 3/8" to 1"

• Easy-access hinge design reduces maintenance time

• Maintenance-friendly design installs quickly and easily

• It applies downward pressure onto belt's surface to create a tight seal

• Continues to self-adjust throughout the life of the dust seal, so there is no need for manual adjustment

• Reduces drag on conveyor system, up to 60% less than rubber seals

• Available in continuous lengths up to 60'

• Quick weld- or bolt-in installation

• MSHA-accepted, flame-retardant formulas available

• Tear-resistant

• Available as a system with Wedge-Loc mounting rail

• Two-part skirt featuring a ¾" primary seal combined with a flexible secondary seal to keep material and dust contained on belt

• Available in Front Line™ flame-retardant urethane which is MSHA approved for underground mine use

• Solid galvinized 12 ga steel mounting rail

• Easy-access hinge design reduces maintenace time

• Accepts skirting thicknesses from 3/8" to 1"

• Quick weld- or bolt-in installation

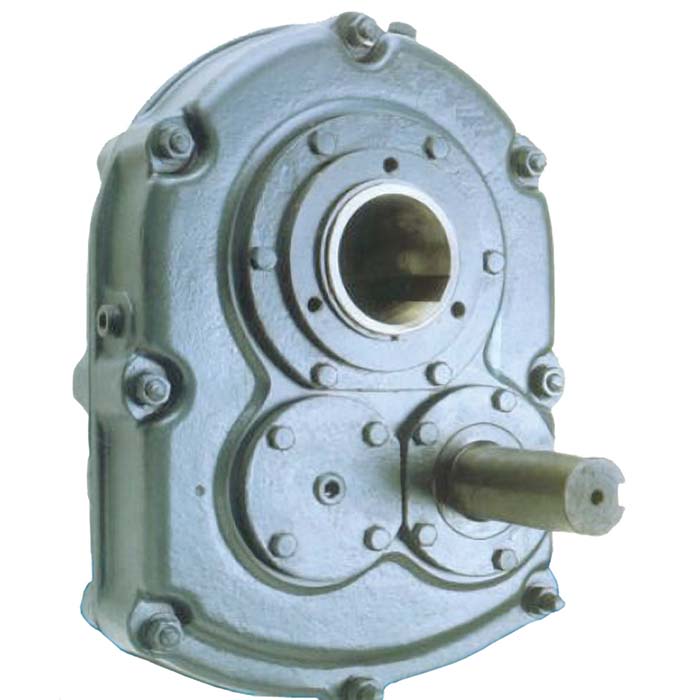

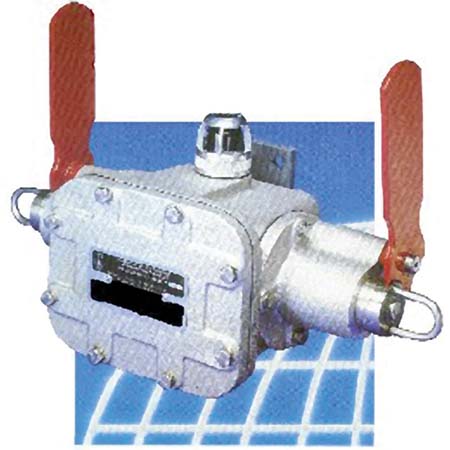

GEARBOXES - Dodge, Browning, Link Belt and Falk

Shaft Mounted Drives • Speed reducers • Seal Kits

GEARBOXES ACCESSORIES

Sheaves • Sprockets • V-Belts • Bushings • Roller chain • Hold Backs

CONVEYOR SWITCHES

The Model RS is a heavy-duty safety control that provides a positive shut off of dangerous equipment in an emergency. A cable pulled by endangered personnel actuates the control. The output contacts of the Model RS-2 can control up to two seperate circuits, one for machinery shutdown and one for an alarm.

The Model PC is a rugged compact safety switch that provides a quick positive shut off of dangerous equipment in emergencies or normal operation. It is actuated by cable pulled by endangered personnel. The output contacts of the Model PC can control up to two separate circuits, one for machinery shutdown and one for alarm.

The Model RSC is a compact safety switch that provides a positive shut off of dangerous equipment in an emergency or for normal operation. A cable pulled by endangered personnel actuates it. The output contacts of the Model RSC can control up to two separate circuits, one for machinery shutdown and one for an alarm. Two versions of the Model RSC have the built-in advantage of cable break detection. Another version acts as a standard cable pull switch, while a fourth version is a palm button (only) for punch presses and other indoor equipment.

The Model TA is a belt mis-alignment control that provides an indication when a conveyor belt has drifted off to a dangerous misalignment condition. The output contacts of the Model TA can control up to two separate circuits, one for machinery shutdown and one for an alarm.

The Model FS is designed to provide indication of presence or absence of dry bulk material on a conveyor belt. Each unit is equipped with one or two output micro-switches which can provide a positive shut off. The output contacts of the Model FS can control up to two separate circuits, one for machinery shutdown and one for an alarm.

The Model BA is a heavy-duty conveyor belt mis-alignment switch that either provides an indication or a shut off of the conveyor during a drift condition in order to prevent further damage to the conveyor belt. The output contacts of the Model BA can control up to two separate circuits, one for conveyor shutdown and one for an alarm.

TThe Model VA is the newest belt alignment control specifically designed for use with bucket elevators. The unit is typically used in pairs to provide protection to both sides of the elevator leg, and indicates when the vertical belt strays or drifts beyond acceptable limits. After such time, the unit will trip an output to indicate a problem, or can be used to shut down the leg until inspection and correction is provided.

RADIO REMOTE CONTROL SYSTEMS

Our Wampfler systems provide three different models of radio controls to best meet the specific needs of our customers. All models are produced with AUTEC's unique code key principle whereby each transmitter has its own embedded serial number - unique in the world and completely tamper - proof. Only the receiver which contains the matching serial number will respond to its commands.

For over 45 years Control Chief Corporation has been the leader in designing, manufacturing and servicing Industrial Remote Control, serving a wide variety of industries.

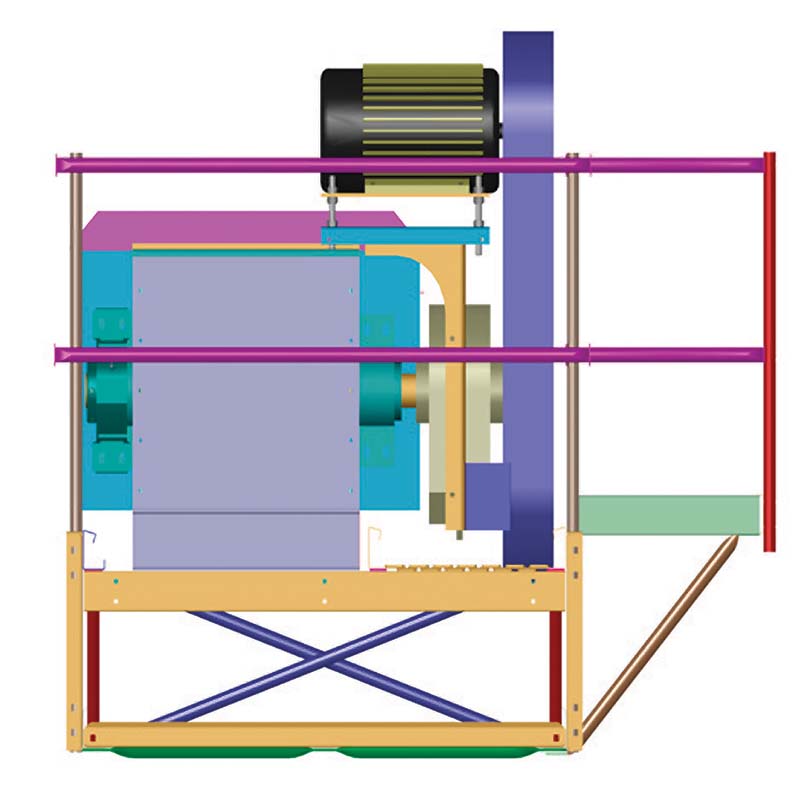

INDUSTRIAL BUCKET ELEVATORS

THE MOST VERSATILE BUCKET ELEVATOR

Used for a wide range of products and many applications. Fully spaced buckets easily accommodate larger particle sizes.

Setting the standard for the industry, dependable Sweet® Centrifugal Discharge and Continuous Discharge Elevators on belt and chain.

AIR GRAVITY CONVEYING

System uses the forces of gravity to do most of the work without any moving parts. Material is fluidized through a porous media with low pressure air.

Material flow is achieved by sloping the Airslide conveyor to match the fluidized angle of repose of the powdered material.

At the correct slope, fluidized materials flow with the consistency of a liquid.

Fluidized Gravity Conveying Systems - Economical, energy-efficient • High capacity, high performance • Versatile and reliable

We supply replacement Air Slide fabric for your Air Slide and in any width or length.

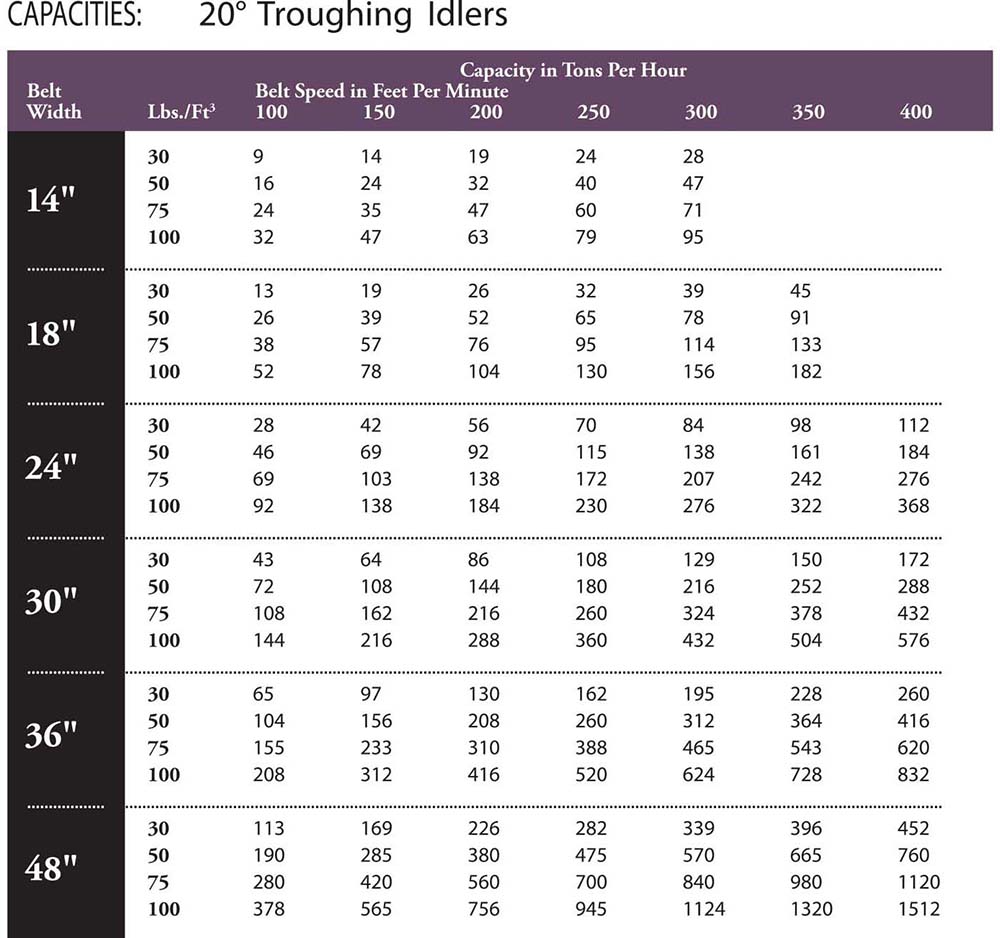

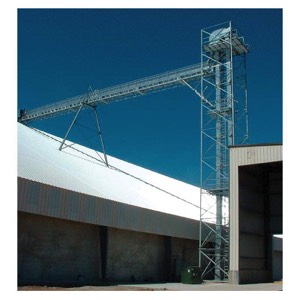

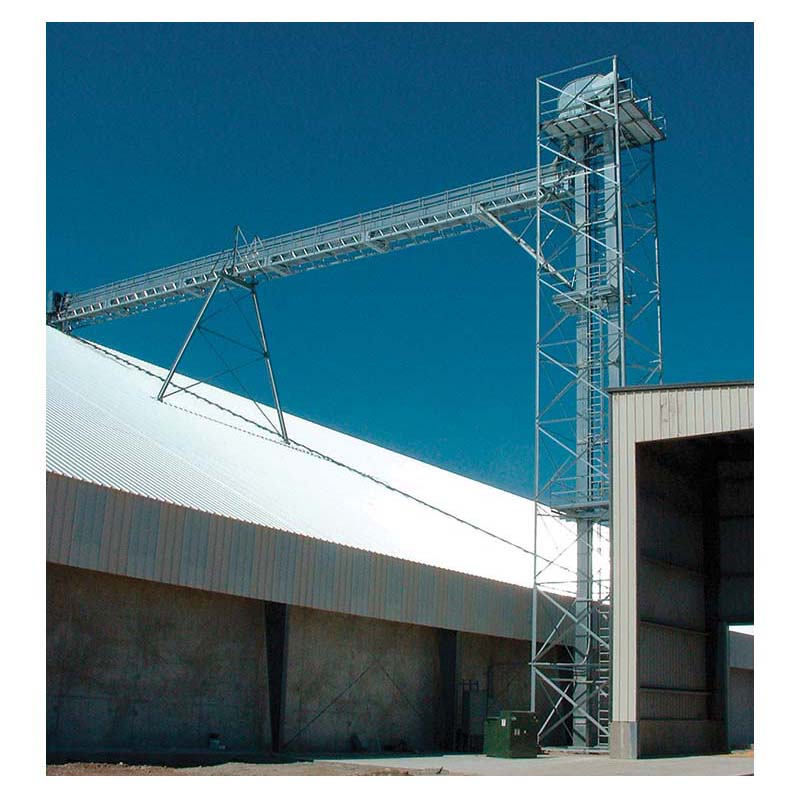

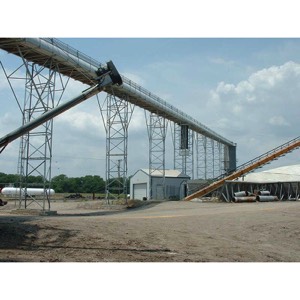

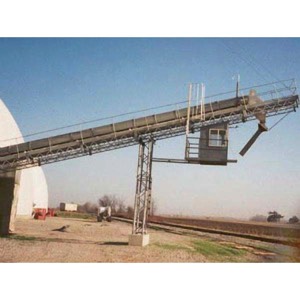

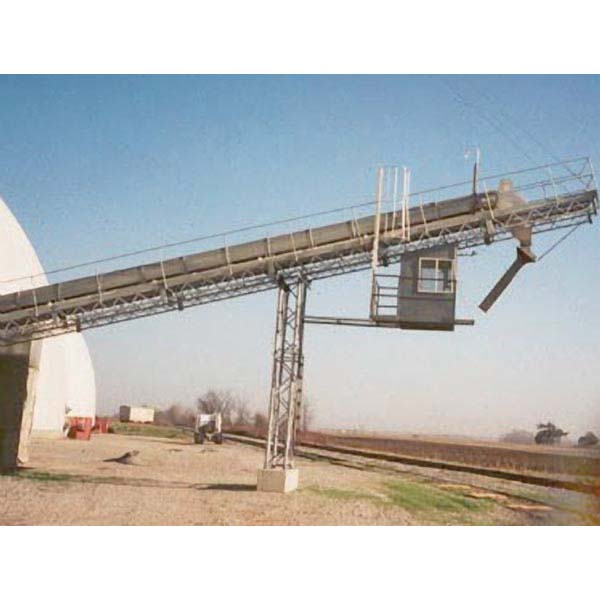

CONVEYORS

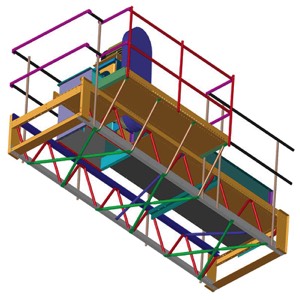

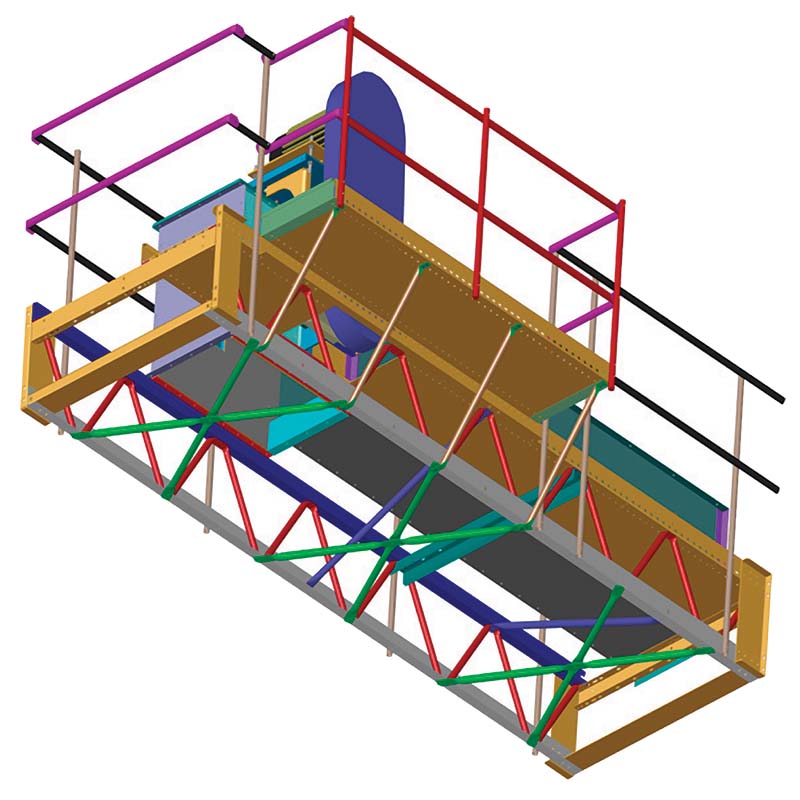

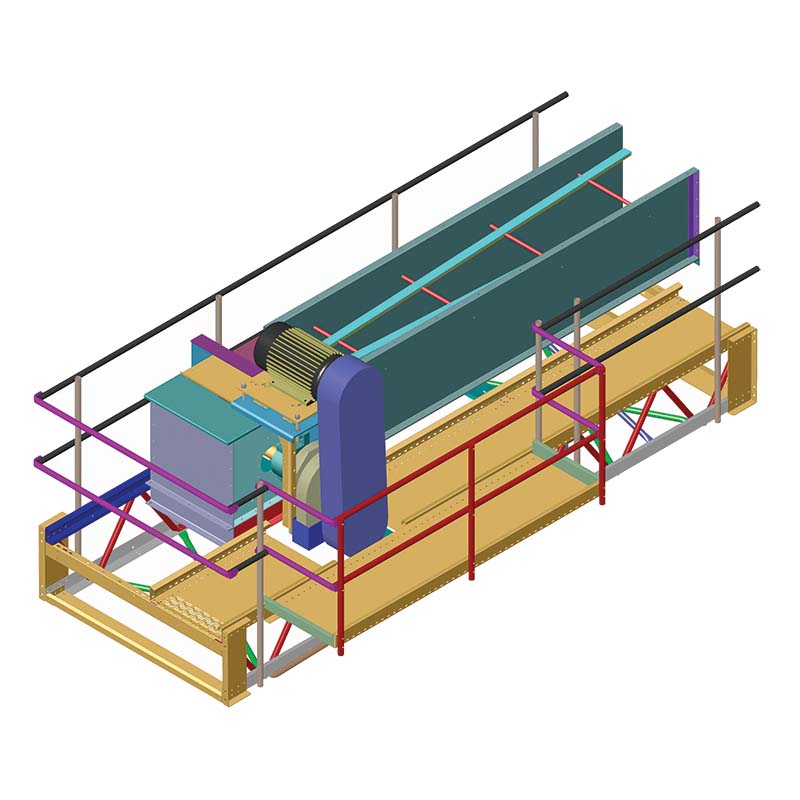

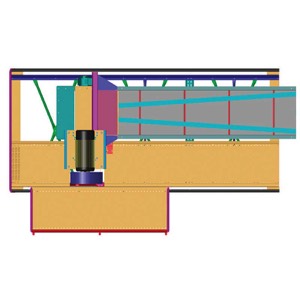

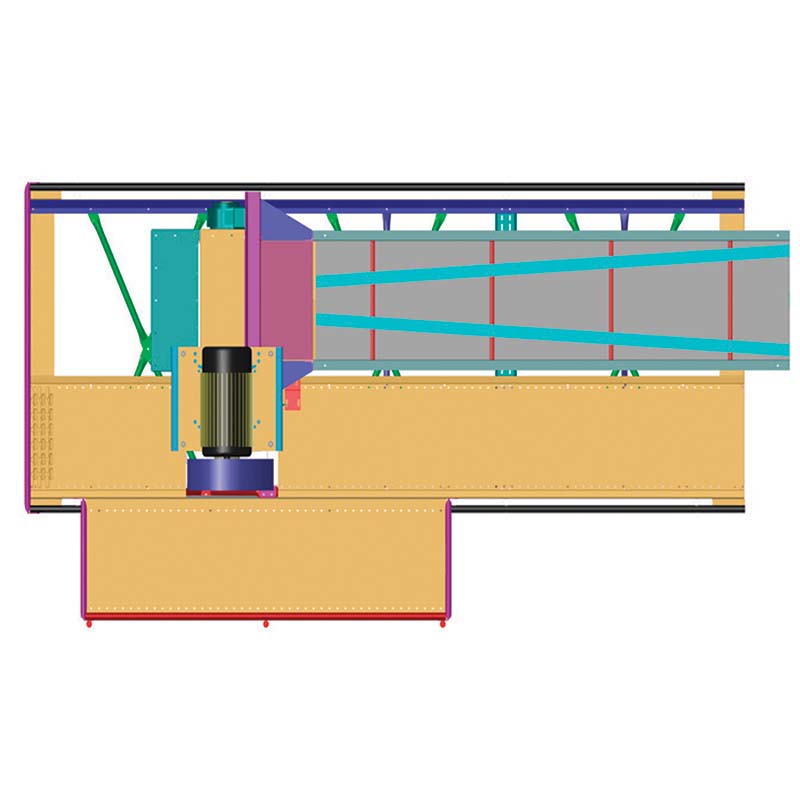

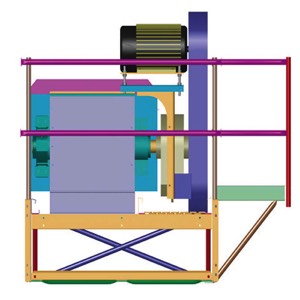

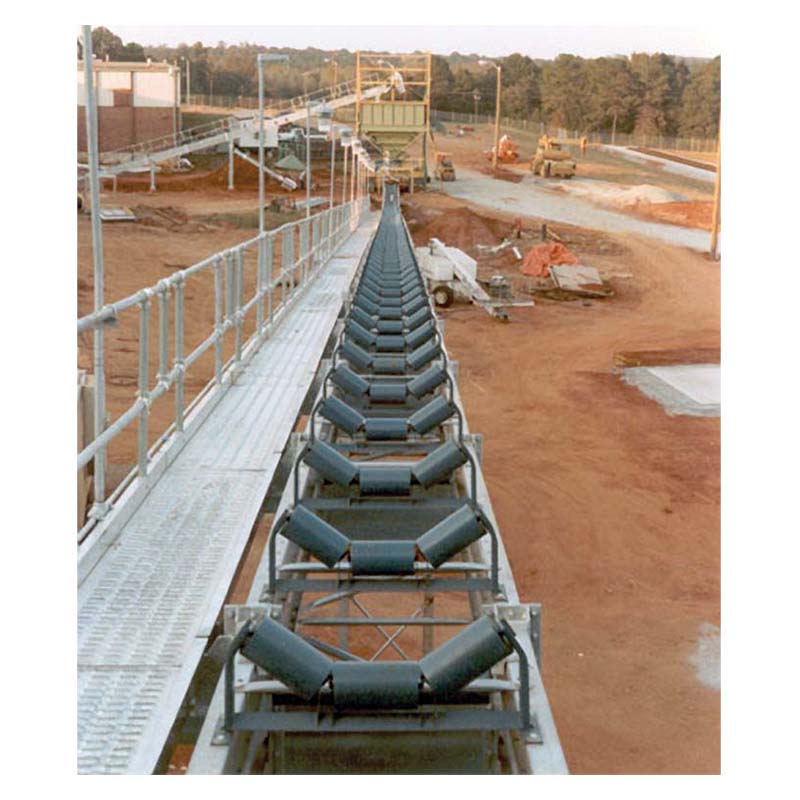

Our Product line-up is set to handle your toughest project needs. From heavy duty transfer Conveyors to custom designed structures.

Conveyors are available in a variety of drives, sizes, lengths, and widths.

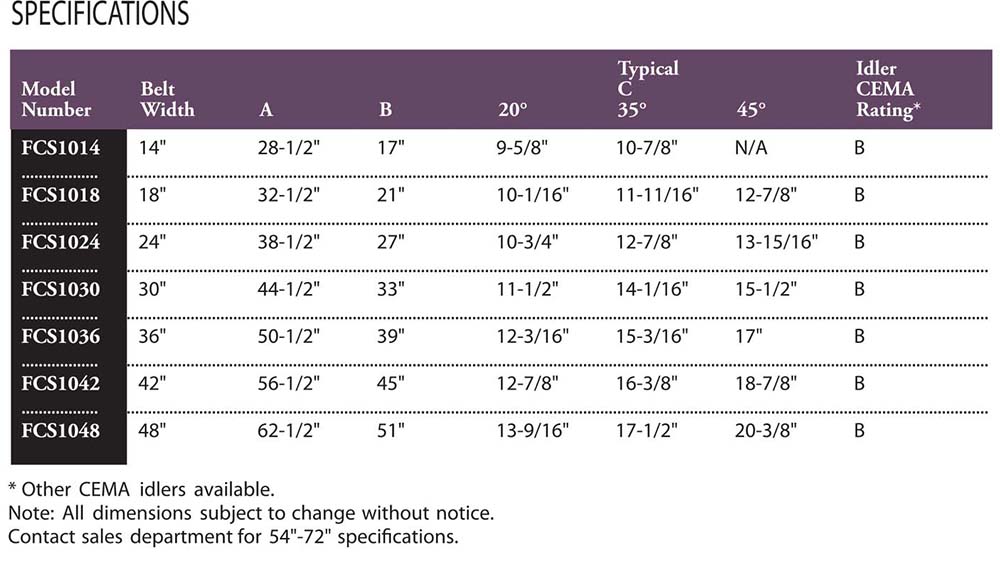

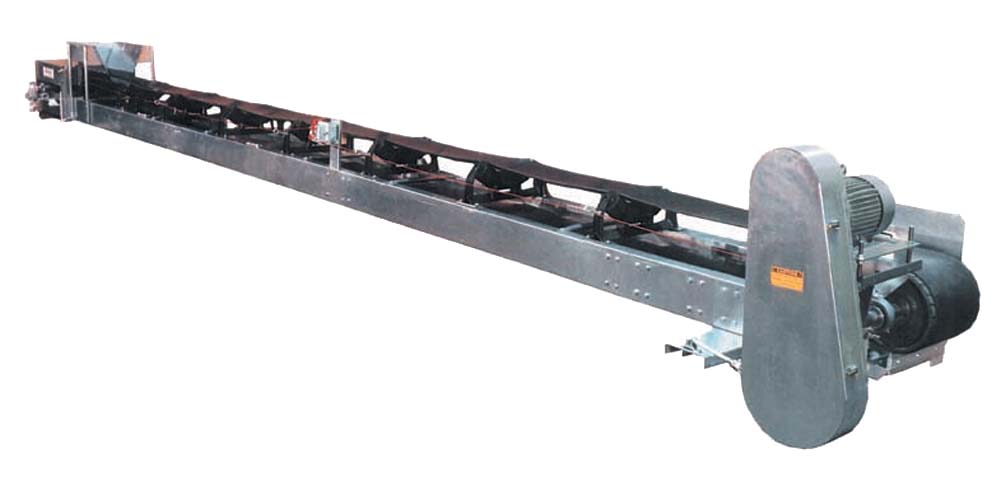

GALVANIZED CHANNEL BELT CONVEYORS

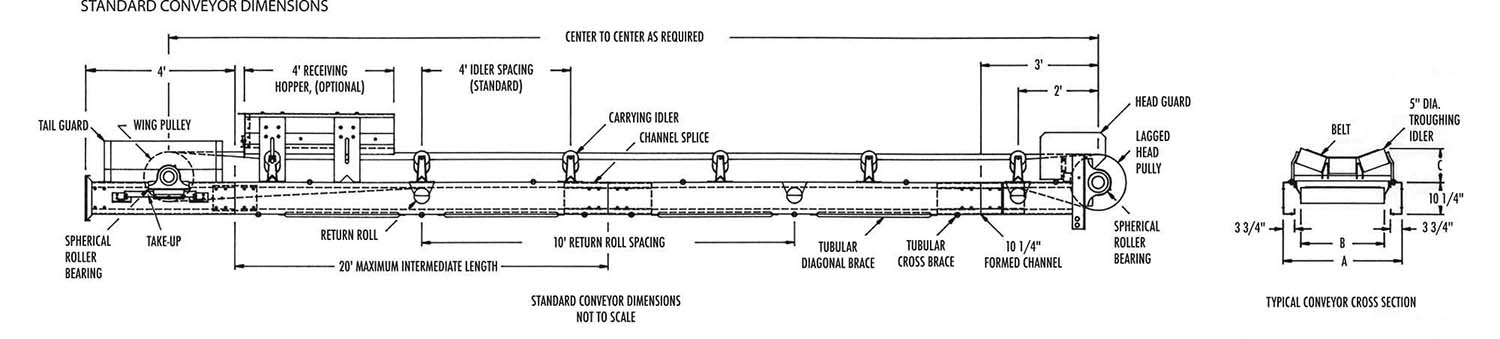

Sweet's Heavy Duty formed channel galvanized steel frame features tubular cross braces and unique diaphragm squaring plate. It will support 565 pounds per linear foot when supports are spaced on 20 foot centers.

Sweet' Belt Conveyors are offered in belt widths from 14" thru 72". Standard head section includes pillow block spherical roller bearings; Turned, Ground, and Polished (TG&P) headshaft; and lagged pulley with bushed hubs. Standard tail section includes self cleaning wing style tail pulley; pillow block spherical roller bearings; and galvanized top mount protected screw take up.

COST SAVING FEATURES

• All bolted construction

• Corrosion resistant Galvanized finish

• Heavy duty formed steel channel frame and channel splice

To figure capacities for 35º and 45º troughing idlers, multiply capacities of 20º idlers shown on left x 1.24 for 35º and 1.33 for 45º. For capacities of belt widths not listed, consult factory.

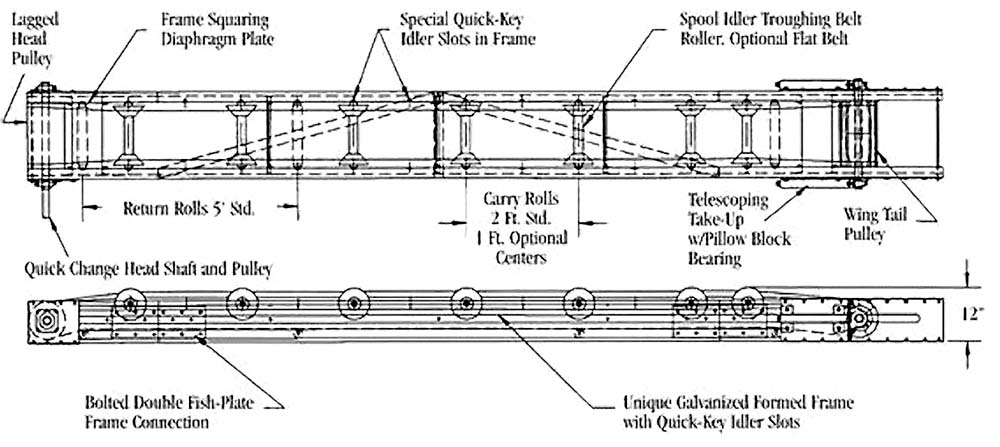

QUICK-KEY SPOOL CONVEYOR

The unique formed rigid design of an all galvanized belt conveyor by Sweet is finding noteworthy user appeal in numerous applications thoughout many industries. This model offers the advantages of a greater span potential combined with a low profile height of 12 inches where space is limited.

Featuring flexibility by design, conveyors are available with various belt widths and include spool idlers with sealed motor grade ball bearings. Quick change key slots, spaced on one foot increments, allow for any combination of idler spacing.

Other significant features include: Lagged drive pulley, wing tail pulley with take-ups, minimum maintenance self-cleaning frame, low horsepower requirements, easy assembly and installation. there are several belt type options and covers can be provided for enclosure against the elements. Options include load skirts, scrapers/brush for belt, 18" deep truss frame to increase free span.

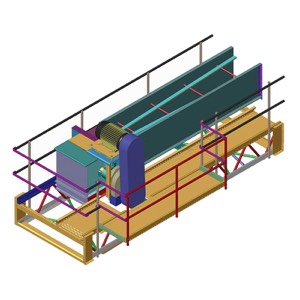

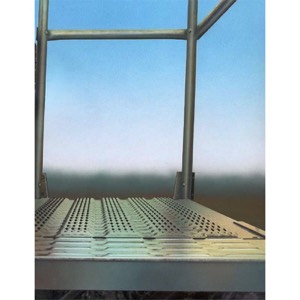

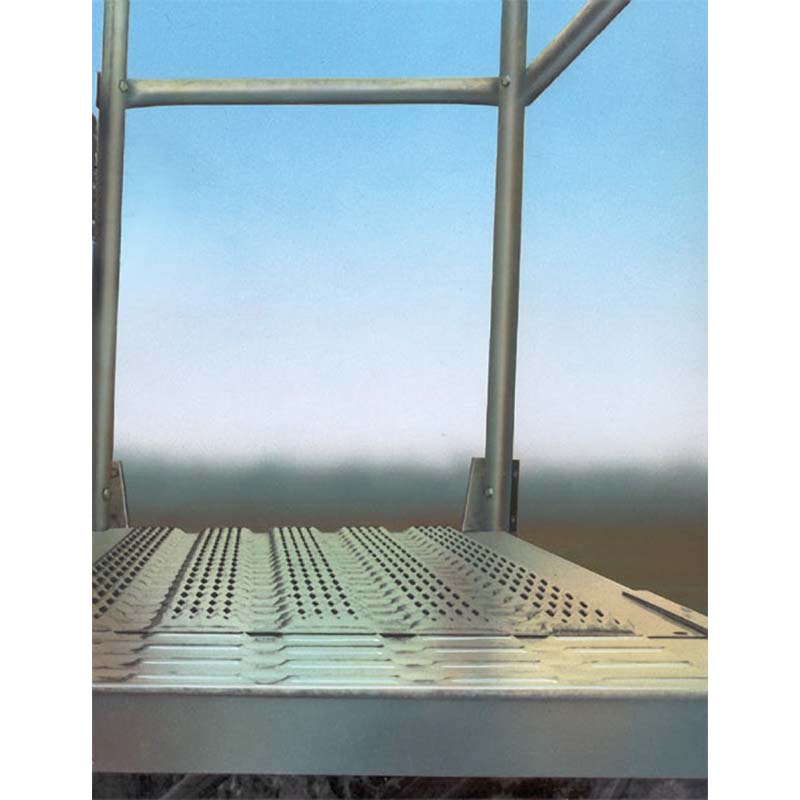

NO MORE CLIMBING OVER DRIVES!

SAFE & SECURE

• Easy to install on existing Silver Span® II Models.

• Standard placement anywhere along walkway, no field modifications.

• Provides additional versatile work surface for head and drive maintenance.

• Safe access around multiple or unique conveyor runs.

• All galvanized, bolted construction for easy installation, no welding required.

• 24”, 30” and 36” Wide

• 18” or 30” Deep Truss

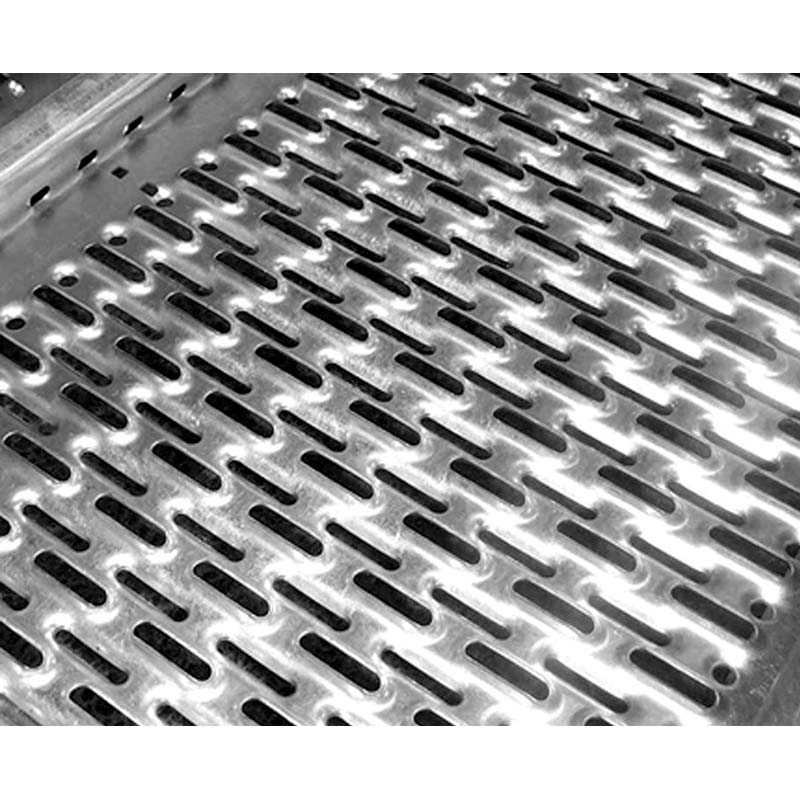

Kit includes Silver Grip® grating, handrail, knee brace supports and hardware.

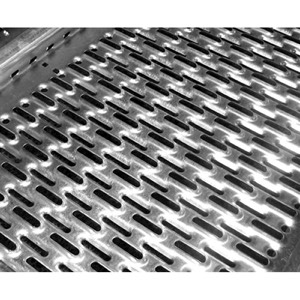

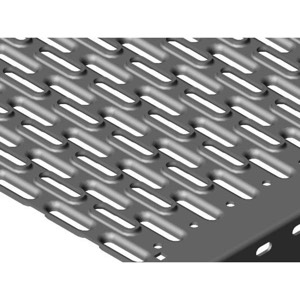

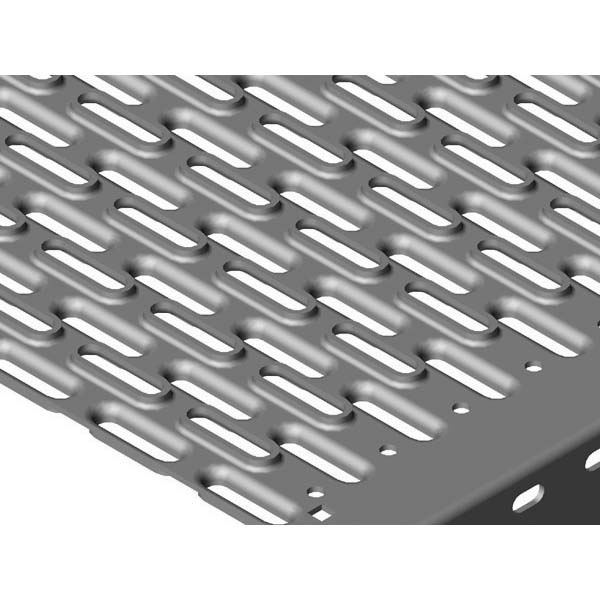

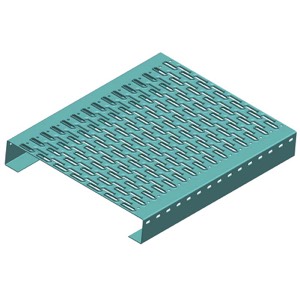

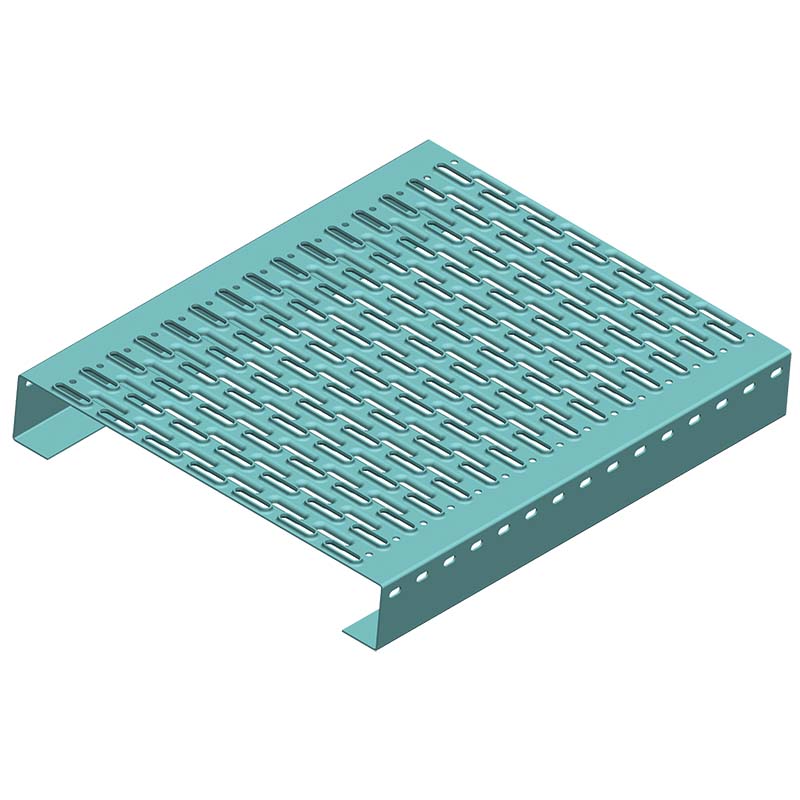

Platform features our Silver Grip® 12 gauge galvanized grating for a safe, non-slip surface. Perforated design eliminates water problems.

7'6" LONG • 40 LBS PER SQUARE FOOT LOADING

CONVEYOR SUPPORT SYSTEM

• Steel for Fast and Easy Modular

• Erection Without Welding,

• Painting or Field Alteration

Hot dipped, Galvanized Structural steel Option Available

Available Lengths:

20' Base Unit 20' Extension Unit

15' Base Unit 15' Extension Unit

10' Base Unit 10' Extension Unit

5' Extension Unit

Size (ft.) 2 x 2* - 10,000 Vertical Load Rating (lbs.)

Size (ft.) 2 x 5* - 20,000 Vertical Load Rating (lbs.)

Size (ft.) 2 x 6* - 20,000 Vertical Load Rating (lbs.)

Size (ft.) 4 x 8 - Capable of supporting on 60 foot centers, a conveyor

and Silver Span at 100 foot high, without guying or bracing.

*NOTE: Must be guyed or braced to structure 30' feet away

Pre-Engineered Galvanized Steel Modular

Conveyor Support Systems and Walkway

• Greater strength for larger conveyors requires less support towers.

• Engineered to meet today's market needs!

• 5', 10', 15', and 20' modular standard section lengths

• 18" and 30" truss

• 24", 30", and 36" wide walkway with built-in toeboard

• Up to 48" wide conveyor area

• Up to 60" wide maintenance area available

• All galvanized steel construction

• Silver Grip® grating walkway

• Bolted construction, no welding required

• Designed to meet all known safety and OSHA requirements

• Free span to 100' or more

• Integral service platforms and intermediate support towers available

Looking For...

• Easier installation?

• Lower installation cost?

• Maintenance free?

• Safe support systems?

• No field cutting or welding?

• Versatility?

• Longer life?

Silver Span® has it all.

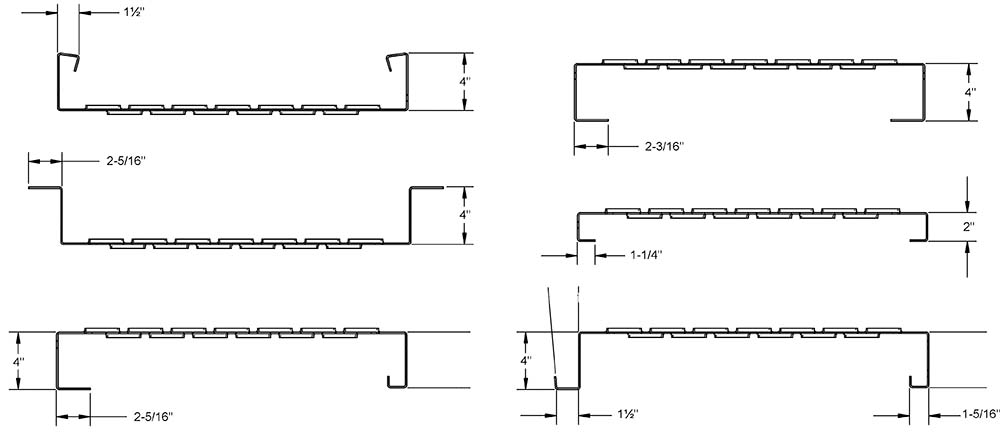

SILVER GRIP CONVEYOR GRATING

Safe, Secure Footing for Work Areas, Platforms, Steps, and Walkways

• Rugged one piece construction.

• Slip-resistant, perforated surface.

• Variable configuration for flexibility.

• Precision side holes for bolting sections.

• 12 gauge — 10’ and 20’ in-stock lengths.

• Custom lengths & configurations upon request.

Aeration & Blowers • Air Line Control • Boots • Cement Screws & Loading Spouts • Concrete Plants • Conveyors • Dust Control System • Level Controls • Mixers • Valves & Cylinders • Vibrators • Water & Moisture Meters & Pumps • Wear Liners

C & G Equipment ● 3590 NW 96th Ave. ● Hollywood, FL 33024 ● Phone: (954) 602-1265 ● Fax: (954) 602-1275