C & W DUST COLLECTORS

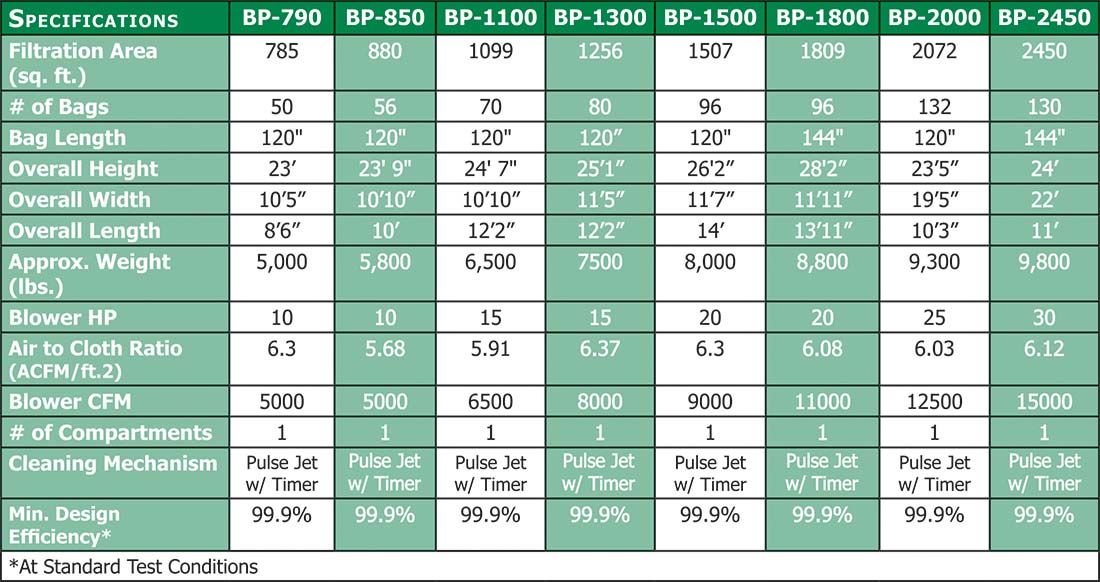

Bag-Pulse Jet (BP) Central Dust Collector

The Bag Pulse Jet Series (or Pulse Jet-Bag) combines advanced Bag Pulse Jet technology with our efficient filter bags and C&W dependability to create a unique dust control system. The BP series highlights tool-less media exchange, high cleaning capacity, and top loading of filter media. C&W's Bag Pulse Jet Series offer superior quality for your concrete and cement dust collection needs.

• Easy to Maintain

• Tool-less Exchange of Filter Media

• Top Entry for Clean Side Filter Exchange

Efficiency

• 99.9% Filtration Efficiency*

• High Level Entry for Contaminated Air

• Snap-in Bags / Cages with Venturi

Performance

• Magnehelic Gauge

• Laser Aligned Cleaning System

• Hopper Vibrator

• Electrical Control Panel

• Solid State Adjustable Timers w/ LED Display

Long-Lasting, Durable

• 10 Gauge, Corrugated Steel Construction

Safety, OSHA-Compliant

• Ladders, Platforms, and Handrails

• Manual or Automatic Recycle Systems

• Custom Shrouds and Snorkels

• Silo Anti-Overfill System

• Screw Conveyor with "V" Hopper

• On Demand Smart Systems

• Available in Mobile Units

• Additional Services:

• Turn-Key Installations

• Customized Layouts

• Start-up and Maintenance Training

• Professional Consultation

C&W's BP Dust Collectors (or Bag-Pulse Jet) uses a brief burst of high-pressured air to clean the filter media (bags). The air flows from the outside to the inside of the filters. Dust is collected on the outside of the bags as the contaminated air passes through. This direction of air flow requires the use of cages inside the bags. As the pulse of air is directed through blow tubes, down the inside of the filters, the dust is blown off. It then falls and is collected for a short time in the hopper below, where it is available to be recycled by the optional recycle system. The entire cleaning process takes around one second. The largest BP Central Dust Collector C&W manufactures is 75,000 CFM, with the smallest offering 850 CFM. Pulse Jet technology is very reliable and effective, but it is also the most expensive among our fabric dust collectors. It requires electrical power, as well as clean, dry compressed air. C&W's BP Series Dust Collectors can be used on numerous dust applications, including but not limited to: Cement, Chalk, Clay, Coal, Coke, Fly Ash, Glass, Gold Ore, Grain, Gypsum, Paint Pigments, Sands, Salt, Slate, Soap, Talc, and Wood.

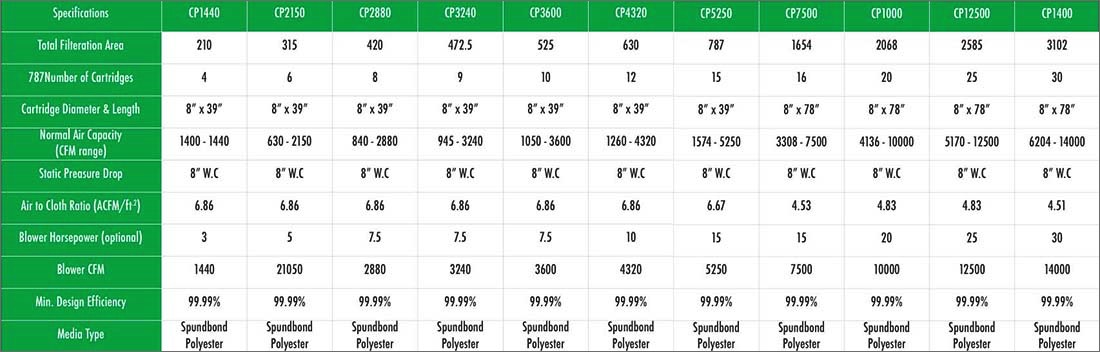

CARTRIDGE PULSE (CP) CENTRAL COLLECTOR

C&W's Cartridge Pulse Dust Collectors combine pulse-jet technology and our vertical cartridge filters to provide a highly effective, yet inexpensive solution for dust control. Cartridge Pulse units are similar in all respects to the Pulse Jet-Bag technology, except for the use of cartridges as the filter media, rather than bags. The use of cartridges increases the filtration area and reduces the number of filters needed. As a result, the dust collector is not as large and offers the most efficient filtration available at 99.99% efficiency. Other attributes of this collector are a space saving footprint, tool-less media exchange, and top loading filter media.

• Easy to Maintain

• Tool-less Exchange of Filter Media

• Top Entry for Clean Side Filter Exchange

Efficiency

• 99.99% Filtration Efficiency*

• Spun-Bound Polyester Filter Media

• Solid State Adjustable Timers w/ LED Display

Long-Lasting, Durable

• 10 Gauge, Corrugated Steel Construction

Safety, OSHA-Compliant

• Ladders, Platforms, and Handrails

• Vertical, Wide-Pleated Cartridges

Performance

• Mini-helic Gauge

• Hopper Vibrator

As with the Pulse Jet-Bag, the Cartridge Pulse collectors require electrical power and clean, dry compressed air set at 80 PSI. The largest CP Central C&W manufactures is 50,000 CFM, with the smallest collector offering 400 CFM. C&W's CP Series collectors can be used on numerous dust applications, including but not limited to: Cement, Chalk, Clay, Coal, Coke, Fly Ash, Glass, Gold Ore, Grain, Gypsum, Paint Pigments, Sands, Salt, Slate, Soap, Talc, and Wood.

• Manual or Automatic Recycle Systems

• Custom Shrouds and Snorkels

• Silo Anti-Overfill System

• Screw Conveyor with "V" Hopper

• On Demand Smart Systems

• Available in Mobile Units

Additional Services:

• Turn-Key Installations

• Customized Layouts

• Start-up and Maintenance

Training

• Professional Consultation

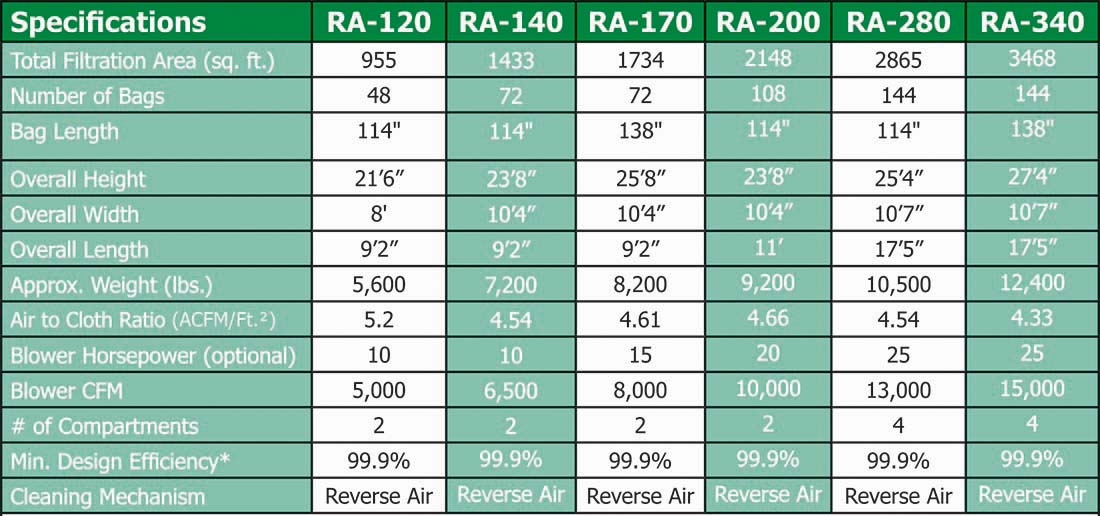

REVERSE AIR ( RA ) CENTRAL COLLECTOR

C&W's Reverse Air Dust Collector is our most popular unit because of its ruggedness, durability, user-friendliness, and proven-technology. Reverse Air dust collectors have multiple compartments that are configured very similar to the old style shaker units. Dirty air enters the bottom of the filter bags and dust is collected on the inside of the fabric. The compartments are cleaned in a sequence, set by adjustable timers.

FEATURES:

• Tool-less Exchange of Filter Media

• Top Entry for Clean Side Filter Exchange

Efficiency

• 99.9% Filtration Efficiency*

• High level Entry for Contaminated Air

• Snap-in Bags/Cages with Venturi

• Ladders, Platforms, and Handrails

Options:

• Manual or Automatic Recycle Systems

• Custom Shrouds and Snorkels

• Silo Anti-Overfill System

• Screw Conveyor with "V" Hopper

• On Demand Smart Systems

• Available in Mobile Units

• Mini-helic Gauge

• Hopper Vibrator

Reliable, Easy to Operate

• Solid State Adjustable Timers w/ LED Display

Long-Lasting, Durable

• 10 Gauge, Corrugated Steel Construction

Safety, OSHA-Compliant

• Ladders, Platforms, and Handrails

Additional Services:

• Turn-Key Installations

• Customized Layouts

• Start-up and Maintenance Training

• Professional Consultation

The Reverse Air design uses low-pressure air to collapse the bags. The bags clean as they are collapsed and re-inflated a number of times. The collected material then falls to the hopper below, where it is available to be recycled by the optional recycle system. This type of collector is more expensive than the shaker design, but the advantage of multiple compartments allows for higher dust concentrations and continuous use. As a compartment is cleaning the bags, the remaining compartments filter the air. The Reverse Air unit works well for material that is easily removed from filter media. The Reverse Air requires electricity and minimal compressed air.

The largest RA Central C&W manufactures is 75,000 CFM, with the smallest offering 5000 CFM.

C&W's RA Series Collectors can be used on numerous dust applications, including but not limited to: Cement, Chalk, Clay, Coal, Coke, Fly Ash, Glass, Gold Ore, Lime, Gypsum, Paint Pigments, Sands, Salt, Slate, Soap, and Talc.

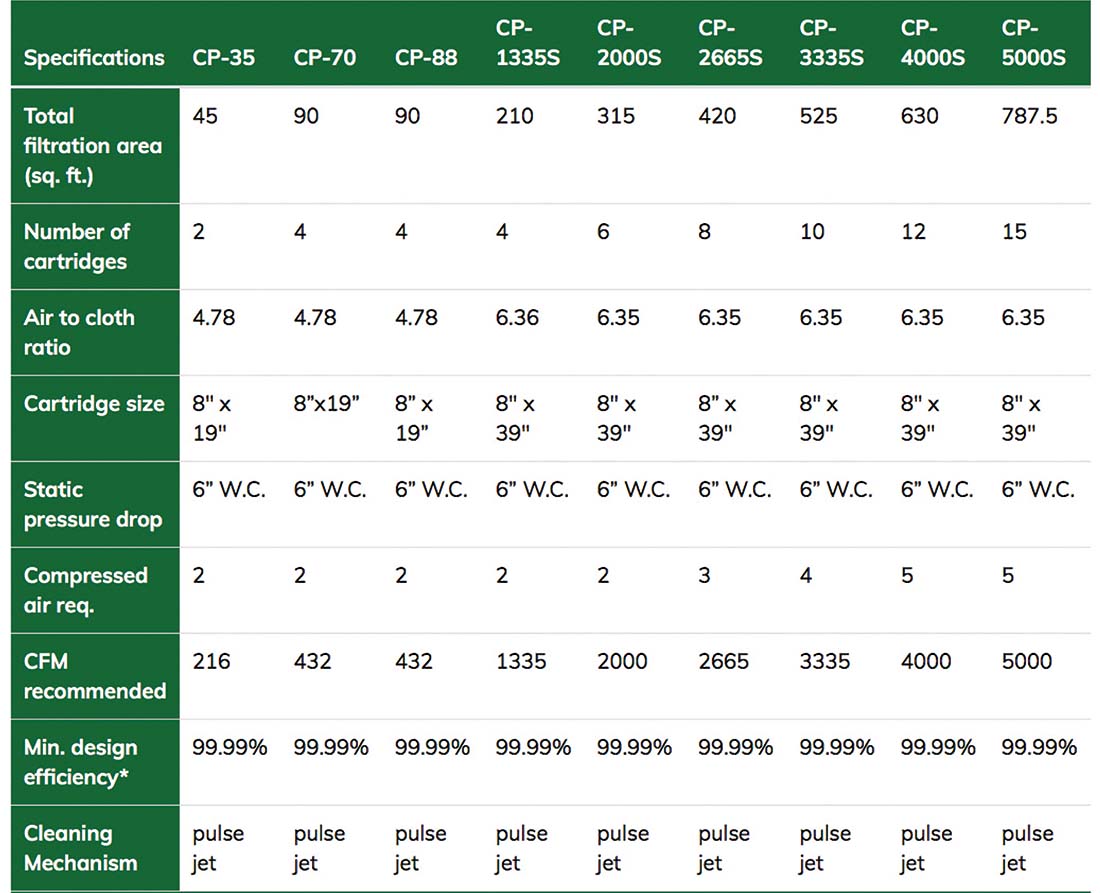

C & W DUST COLLECTORS • SILO DUST COLLECTORS • CARTRIDGE PULSE (CP) SILO COLLECTORS

C&W's traditional Cartridge Pulse Silo Collector features Pulse-Jet technology, 99.99% filtration efficiency, and tool-less media exchange. Numerous models of this unit offer varying degrees of filtration, ranging from a Weigh Scale Collector with 36 ft. of filtration area to a CP-5000 with 2,673 ft. of filtration area.

• Easy to Maintain

• Tool-less Exchange of Filter Media

• Top Entry for Clean Side Filter Exchange

Efficiency

• 99.99% Filtration Efficiency*

Efficient, Compact

• Vertical, Wide-Pleat Cartridges

Options:

• Pressure Switch for Automatic Cleaning

• Mini-helic Gauge

• Custom Designs and Sizes

• Special Mounting Flange for Adapting to Existing Flange

• Blower Packages, Standard or Custom-Built

• Special Filter Media

• Silo Anti-Overfill System

• Pressure Relief Valves and Bin Indicators

• Inlet Air Regulator and Moisture Separator

• Test Ports for Monitoring Filter Media

Reliable, Easy to Operate

• Solid State Adjustable Timers w/ LED Display

Long-Lasting, Durable

• 12 Gauge, Heavy Duty Steel Construction

Applications:

• Cement

• Chalk

• Clay

• Coal

• Coke

• Fly Ash

• Glass

• Gold Ore

• Grain

Basically the same cleaning operation as Pulse Jet-Bag, except instead of bags for the filter media, cartridges are used, which provide higher filtration efficiency at 99.99%.

The largest traditional CP-Silo Collector C&W usually manufactures is 5,000 CFM, with the smallest offering 216 CFM.

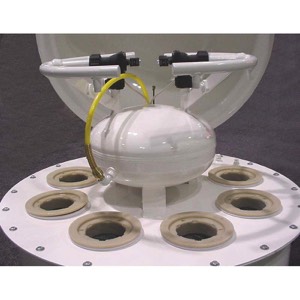

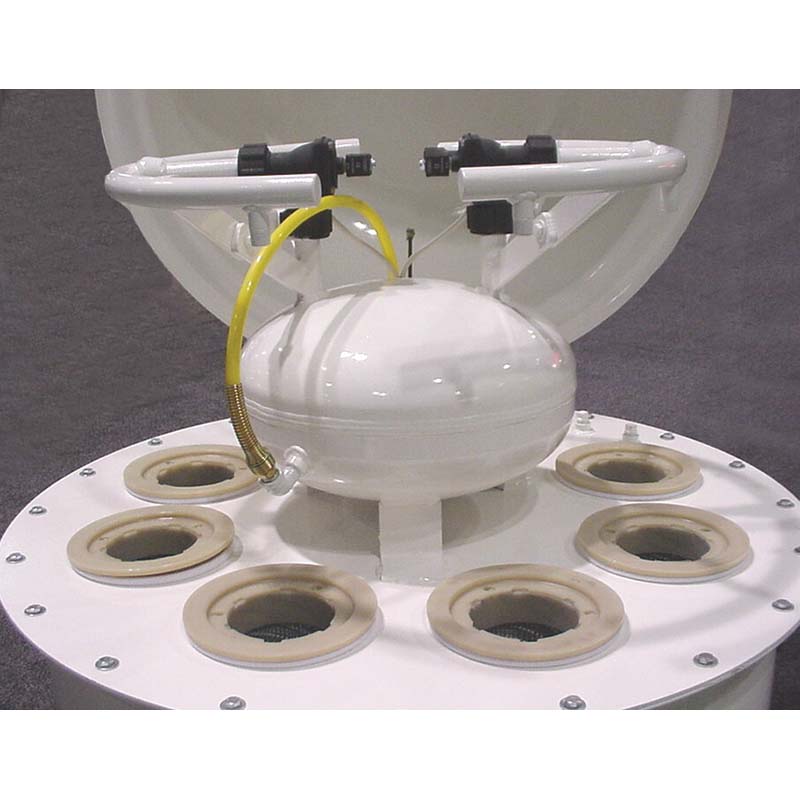

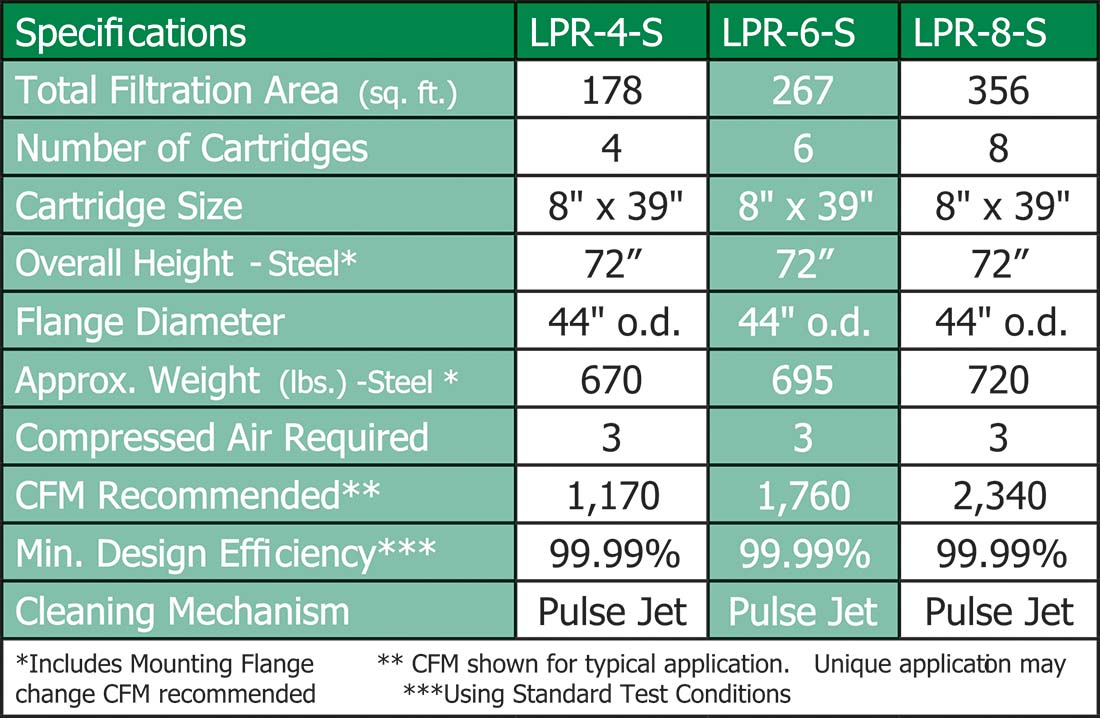

LOW PROFILE ROUND (LPR) SILO COLLECTOR

Low-Profile Round (LPR) Silo Collectors are unique because they offer expandable filtration area to meet your rising production demands, with out having to replace unit. These units come standard in a steel housing, and are available with either 4, 6 or 8 cartridges depending on your production. C&W has years of experience working with small units designed for intra-silos, as well as large silos where the collector handles the continuous dust loading needs from cement terminals to ship unloading facilities.

We developed the LPR Silo Collector as a direct result from customer requests for a low working surface area and is able to expand its filtration capacity as our customers business develops and expands.

LPR Silo Collectors are available in Pulse-Jet technology, with our cartridge filters, providing the most efficient filtration available at 99.99% filtration efficiency.

• Lightweight - Units range from approximately 670-750 pounds.

• Low 46" Working Height

• Filters Pop in-out with no tools needed

• Expandable filtration capacity - accomplished by merely adding cartridges to the unit which increases the filtration area, without replacing the unit

• Blow pipes built & placed in the interior of the unit

• Vertical, wide, pleated cartridges - offering 99.99% filtration efficiency

• Solid State Timer Board

• Pulse Air shut-off safety switch

• Lifting lugs for crane mounting

• Air Regulator

• Gauge ports

• Automatic On/Off Flow Switch

• Minihelic Gauge

• Special Adaptable Mounting Flange

• Air Tank Auto-Drain

• Silo Anti-Overfill System

• Pressure Relief Valves and Bin Indicators

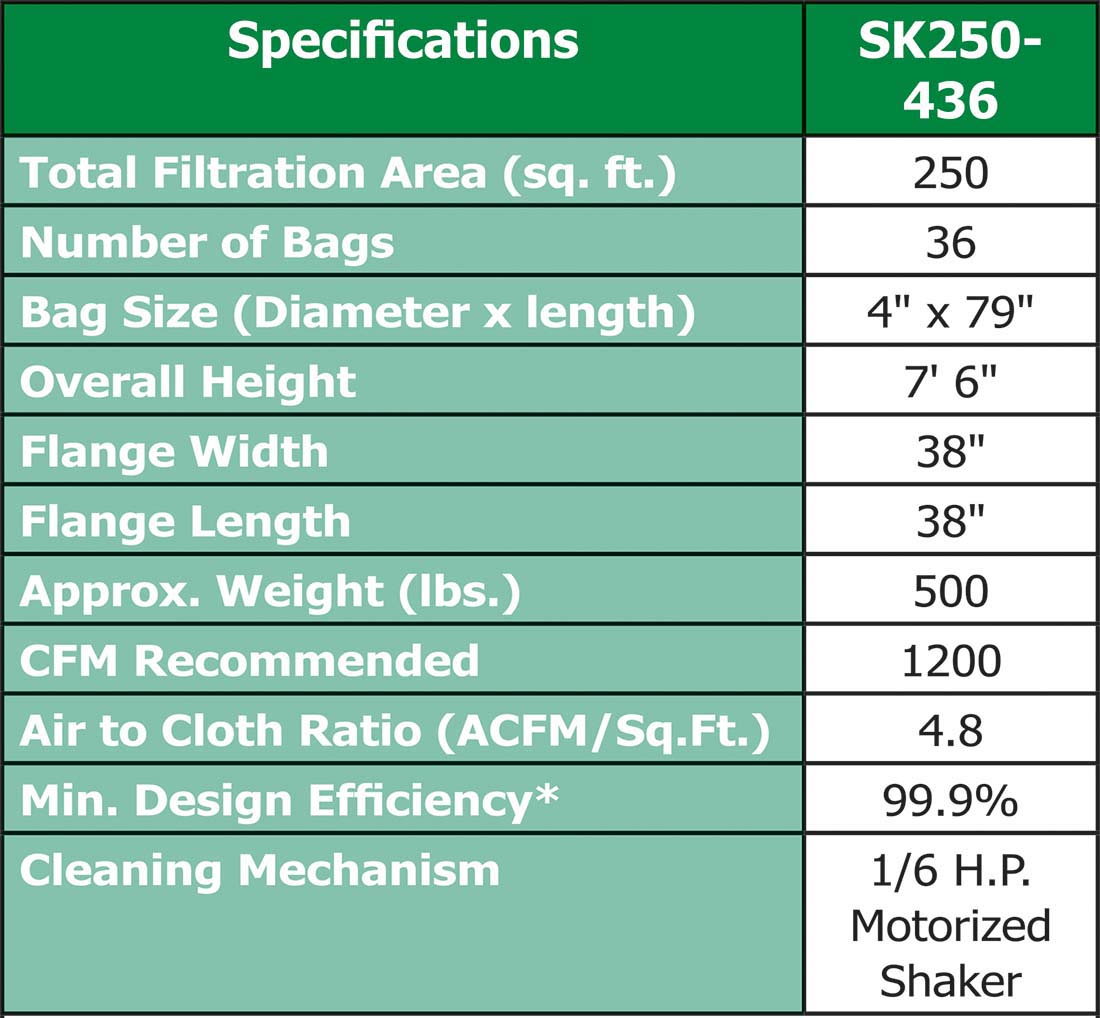

SHAKER SILO COLLECTOR

This unit is designed for producers in sub zero weather conditions because this unit is not susceptible to freezing, as no compressed air is required. C&W's Shaker Silo Collector also features 99.9% filtration efficiency, tool-less media exchange, and is extremely user-friendly.

The optional blower package for this Shaker Silo Collector offers between 850-1200 CFM.

Easy to Maintain

• Tool-less Exchange of Filter Media

• Side Entry for Clean Side Filter Exchange

Efficiency

• 99.9% Filtration Efficiency*

Efficient, Compact

• Polyester Filter Media

Performance

• Handles up to 1200 CFM

• Test Ports for Monitoring Filter Media

Reliable, Easy to Operate

• Gentle, Reliable Mechanical Shaker

Long-Lasting, Durable

• 12 Gauge, Heavy Duty Steel Construction

• Will not freeze when in sub-zero weather

Options:

• Silo Mounting Flange - available in 6" and 12" heights, or an Angle Flange for Sloped Silos

• Blower Package - 2 or 3 HP Blowers offering 850-1200 CFM

• Silo Anti-Overfill System

• Pressure Relief Valves and Bin Indicators

• Timer Controlled Automatic Off Switch

The cleaning mechanism for the Shaker Silo Collector is a mechanical shaker which gently yet thoroughly cleans the filter media.

WAM SILOTOP VENTING FILTERS

SILOTOP® is a cylindrically shaped dust collector for venting of pneumatically filled silos. The stainless steel body contains vertically mounted, POLYPLEAT® filter elements. The air jet cleaning system is integrated in the hinged weather protection cover.

Dust separated from the air flow by special POLYPLEAT® filter elements drops back into the silo after an integrated automatic reverse air jet cleaning system inside the weather protection cover has removed it from the filter elements.

Features:

• Compact 800mm (30 in) diameter 304 stainless steel body with bottom flange 24.5m2 (264 Sq Ft) filter surface

• Maintenance height = 1,100mm (3.6 ft)

• High filtration efficiency due to POLYPLEAT® filtering elements

• Low dust emission level due to B.I.A.-certified filter media

• Maintenance-free air jet cleaning unit integrated inside weather protection cover

• Safe weather protection cover with lockable snap hook

• No tools required for filtering element removal

• Robust design

• Perfectly accessible due to compact design

• Complete replacement of filter media by only one person within a few minutes

Options & Accessories:

• Weld-on bottom ring

• Multifunctional electronic differential pressure meter

• Winter protection for solenoid valves

WAMECO® CLAMPED ROUND DUST COLLECTORS

WAMECO® Dust Collectors consist of a cylindrical shape stainless steel casing with tube clamp connection, vertically inserted filter elements, and an automatic reverse air jet cleaning system. WAMECO® Dust Collectors are either built in for venting applications or come as a stand-alone unit with dust collecting hopper. For suction applications fan versions are available.

The cylindrically shaped WAMECO® Dust Collector has been designed to de-dust a large variety of different dust sources. High quality standards allow to successfully solve many de-dusting problems.

The WAMECO® is particularly suitable for pneumatic conveying systems (both suction and pressure-type). High filtration efficiency is guaranteed due to accurate filter media selection and certification by B.I.A.

The WAMECO® Front Dust Collector version, which has elements that can be unscrewed from the dirty side, is used where access to the filter elements from the clean air side is not possible either because of limited headroom or a top-mounted fan.

Performance & Technical Features - Benefits:

• Cylindrical stainless steel body

• Filter surface from 1 to 47m² (11 to 505 sq ft)

• Air volume from 60 to 4,500m³/h (35 to 2,650 cfm)

• Low emission level due to B.I.A.-certified filter media

• Special design compressed air jet cleaning system

• Tight fit of filter media due to push-fit elements

• Multifunctional electronic control panel

• Filtering elements: round bags, elliptical bags, cartridges

• High filtration efficiency due to special WAM® filtering elements

• Easy maintenance due to quick access to filtering elements

• Quick access to filter media from the clean air side or from dirty air side through large access door

• Integrated compressed air cleaning system

• Minimum pressure loss due to special air diverter distribution modules

• Venturi inserts guarantee maximum efficiency of air jet

• Special design air jet blowing system minimizes pressure drop

• Special pre-tensioning device for circular and elliptical bag-type filter elements

• Standard after shut down cleaning cycle

• All components, fittings and instruments, some of which either patented or having patent pending, are special WAM® designs

• Suction fan

• Spigot for centralised suction

• Vibrator cleaning system

• Electronic differential pressure meter

• Dust collection hopper with bucket, butterfly valve, rotary valve, and various types of flow aids

• Winter protection for solenoid valves

• Large front door providing easy access for filtering element removal with WAMECO® Front version

Versions Available

• WAMECO® S-type: BASIC dust collectors for pneumatic pressure or suction conveying systems

HOPPERTOP WEIGH HOPPER VENTING FILTER

HOPPERTOP is a small cylindrical venting filter specifically for installation on weigh hoppers in concrete batching plants.

Function:

HOPPERTOP is a compact venting filter for mechanically filled hoppers. Dust which is separated from the air flow by a single WAM® cartridge filter element drops back into the hopper after an integrated automatic reverse air jet cleaning system inside the weather protection cover has removed the dust particles from the filter elements.

Performance & Technical Features - Benefits:

• Stainless steel flanged body

• Low emission level due to B.I.A.-certified filter media

• Special design compressed air jet cleaning system

• High filtration efficiency due to unique WAM® design filter elements

• Quick maintenance due to easy access for filtering element removal

• Filter surface: 1 m2

• Maintenance-free air jet cleaning unit integrated inside weather protection cover

• High cleaning efficiency due to "Full-Immersion" solenoid valves

• No tools required for filtering element removal

• Minimum maintenance required

• High efficiency

• Minimum space required

• Easy to fit and retrofit

Options & Accessories:

• Emission measurement connection

• Electronic differential pressure meter (MDPE)

• Bottom ring

HOPPERJET

HOPPERJET® is a small footprint venting filter for installation on intermediate storage hoppers or weigh hoppers.

Function:

HOPPERJET® is a compact venting filter for mechanically filled hoppers. Dust which is separated from the air flow by a single POLYPLEAT® or bag-type filter element drops back into the hopper after an integrated automatic reverse air jet cleaning system inside the weather protection cover has removed the dust particles from the filter elements.

Performance & Technical Features - Benefits:

• 304 stainless steel flanged body

• Low emission level due to B.I.A.-certified filter media

• Special design compressed air jet cleaning system

• High filtration efficiency due to unique WAM® design filter elements

• Quick maintenance due to easy access for filtering element removal

• Maintenance-free air jet cleaning unit integrated inside weather protection cover

• High cleaning efficiency due to "Full-Immersion" solenoid valves incorporated in corrosion-resistant aluminium air tank

• No tools required for filtering element removal

• Minimum maintenance required

• High efficiency

• Minimum space required

• Easy to fit and retrofit

• Spigot for centralised suction system

• Electronic differential pressure meter (MDPE)

• 304 or 316 stainless steel cover

• 316 stainless steel body

Scientific Dust Collectors Manufactures a full line of Baghouse Dust Collectors to meet the needs of your specific operation. For over 28 years, SDC has provided customers with unmatched cleaning performance due to our superior cleaning system that employs a patented supersonic nozzle to clean the filters more effectively than any of our competitors.

TOP REMOVAL

Scientific Dust Collectors' Supersonic Pulse Jet Top Removal (SPJ-T) Collector is designed with a full walk-in plenum for easy bag access from the clean side. It utilizes the patented supersonic nozzle cleaning system as well as a high-side inlet so that the heavier dust falls out of the air stream. These features allow the collector to operate at higher air-to-cloth ratios, lower pressure drops, and provide longer filter life. The SPJ Series is a heavy duty reverse pulse jet dust collector that operates continuously without requiring the process to be shut down for cleaning. The walk-in feature on the SPJ-T Series allows bag changeout from the clean side while not being exposed to the elements. Our high side baffled inlet with dropout section slows to less than 3000 FPM, which allows the large particles to simply fall out of the airstream into the hopper. Our bag spacing of three (3) inches between bags is the widest spacing in the industry. This reduces reentrainment of the dust. Our nozzle based cleaning system eliminates the venturi at the top of the bag/cage. This allows us to get over 300% more cleaning air into the bag than other generic baghouses.We gaurantee a stabilized pressure drop in our baghouse to be lower than 3.5"WC at full rated airflow.

BOTTOM REMOVAL COLLECTOR

Scientific Dust Collectors' Supersonic Pulse Jet Bottom Removal (SPJ-B) Collector is designed for low-profile applications where headroom is a factor. It utilizes the patented supersonic nozzle cleaning system as well as a high-side inlet so that the heavier dust falls out of the air stream. These features allow the collector to operate at higher air-to-cloth ratios, lower pressure drops, and provide longer filter life. This design also has all the same benefits and features as our top bag access designs. The only difference is that the bags are accessed from the dirty air side of the baghouse.

LOW FLOW BOTTOM REMOVAL COLLECTOR

Scientific Dust Collectors' newest Supersonic Pulse Jet Low Flow Bottom Removal (SPJ-BL) Collector is economically designed for low-flow applications (less than 5,000CFM) and low static pressure (less than 14" SP). It utilizes the patented supersonic nozzle cleaning system as well as a high-side inlet so that the heavier dust falls out of the air stream. These features allow the collector to operate at higher air-to-cloth ratios, lower pressure drops, and provide longer filter life.

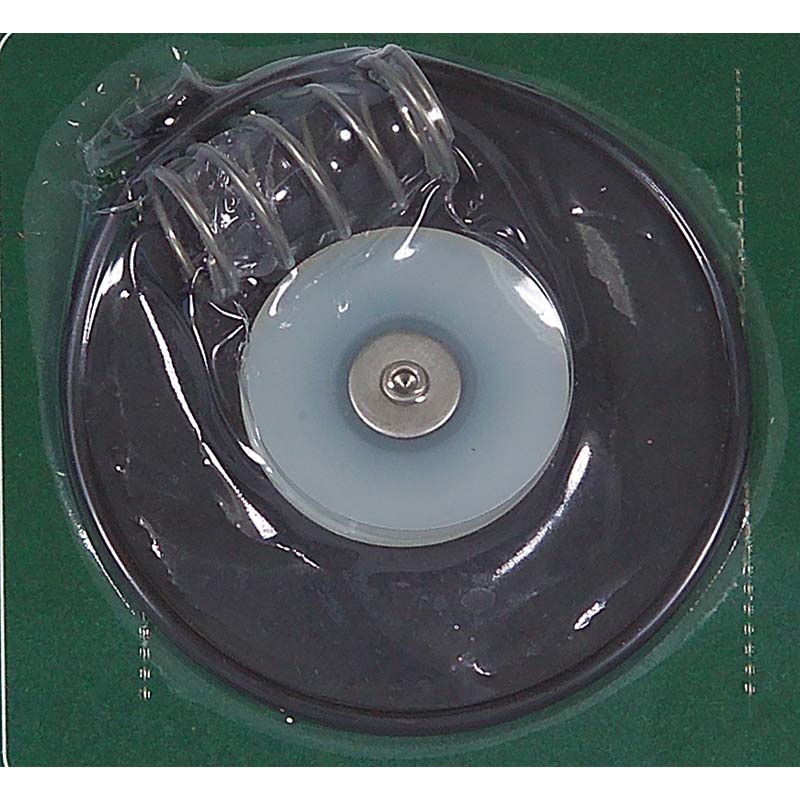

BIN VENT COLLECTOR

Scientific Dust Collectors' Supersonic Pulse Jet Bin Vent(SPJ-BV) Collector is designed specifically for storage tanks, silos, work bins, and material receivers. It employs the patented supersonic nozzle cleaning system which allows the collector to operate at higher air-to-cloth ratios, lower pressure drops, and provide longer filter life. We can provide powered (with a fan) and non-powered (without a fan) bin vents. We can also customize the bottom flange to match customers' required opening.

HORIZONTAL COLLECTOR

Scientific Dust Collectors' Supersonic Pulse Jet Horizontal(SPJ-H) Collector is designed for low headroom applications, similar to the SPJ-B Collector. It utilizes the patented supersonic nozzle cleaning system as well as a high-side inlet so that the heavier dust falls out of the air stream. These features allow the collector to operate at higher air-to-cloth ratios, lower pressure drops, and provide longer filter life. This special design uses horizontal bags that are accessed from the clean side of the unit. This is a specialty application unit where the dust is large and stringy, but there is a low headroom requirement.

DUST COLLECTOR CARTRIDGES & FILTER BAGS

We can supply Pleated Bags, Cartridges or Filter Bags for any Manufacturer or size.

Custom made sizes, High Temp. any Industry including Cages.

DUCTING

LaserLock™ ducting is a modular ducting system available in a range of standard sizes in rolled edge, five foot lengths. The system is complete with bends, blast gate dampers, reducing cones, branch pieces - all joined with lock rings (clamps). The use of lock rings creates a sealed joint and reduces installation time to almost half that of conventional methods of ducting.

We can also supply the older style Spiral Pipe with all accessories.

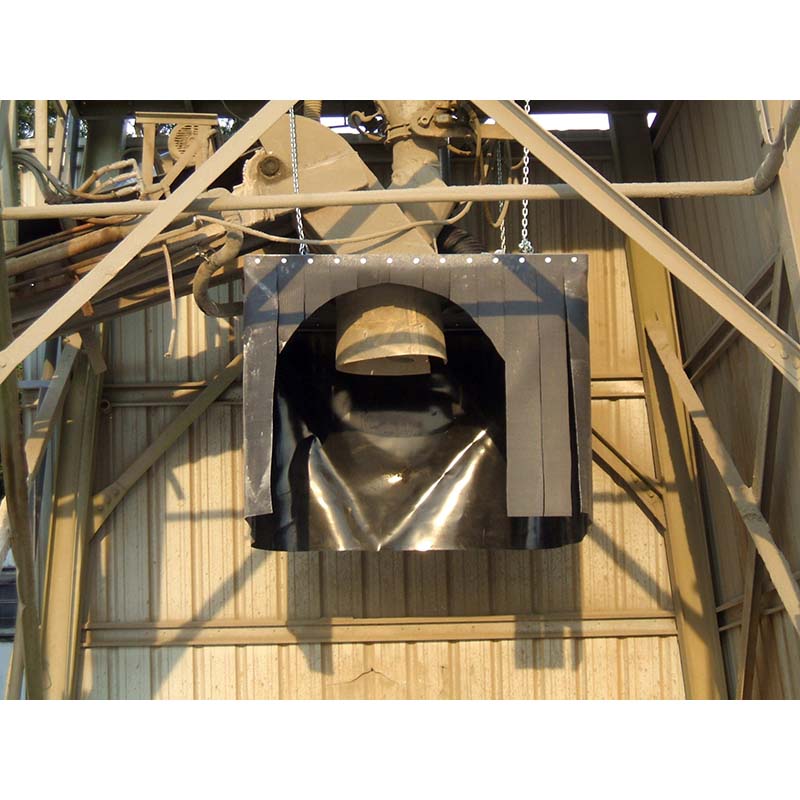

SHROUDS

C&W offers shrouds for back-in drive-out, drive-through, and front discharge truck operations. We also have shrouds to compliment our new Easy-UP duct.

Standard shroud designed for rear-discharge trucks. 6’ 6” x 5’ shroud includes 60” drop rubber curtain, and two (2) 14” pick up points.

• Boost-a-Load Shroud available for Boost-a-Load and front discharge trucks.

• Double Boost-a-Load Shroud available for drive-up or back-in fromeither side.

• BridgeMaster Shroud available for back-in using new MTM™ Bridgemaster trucks

Unique design allows ultra-effective dust control for drive-through operations. The sides and back lift up, allowing the truck to drive through. Includes two (2) 14” pick up points, 60” rubber curtains, four (4) air cylinders and solenoids.

• Expanded Vis-a-Load Shroud available for Boost-a-Load and front discharge trucks.

• Double Expanded Vis-a-Load Shroud available for drive through in either direction

A lift frame allows raising or lowering of the shroud to meet the requirements of various truck heights. Large lift frames (for Boost-a-Load and Double Vis-a-Load Shrouds) includes a 6” air cylinder and inching solenoid, cabling, pulleys, and air hose. Extra Large lift frames use an 8” air cylinder and are used for Double Boost-a-Load or Double OKEL Shrouds.

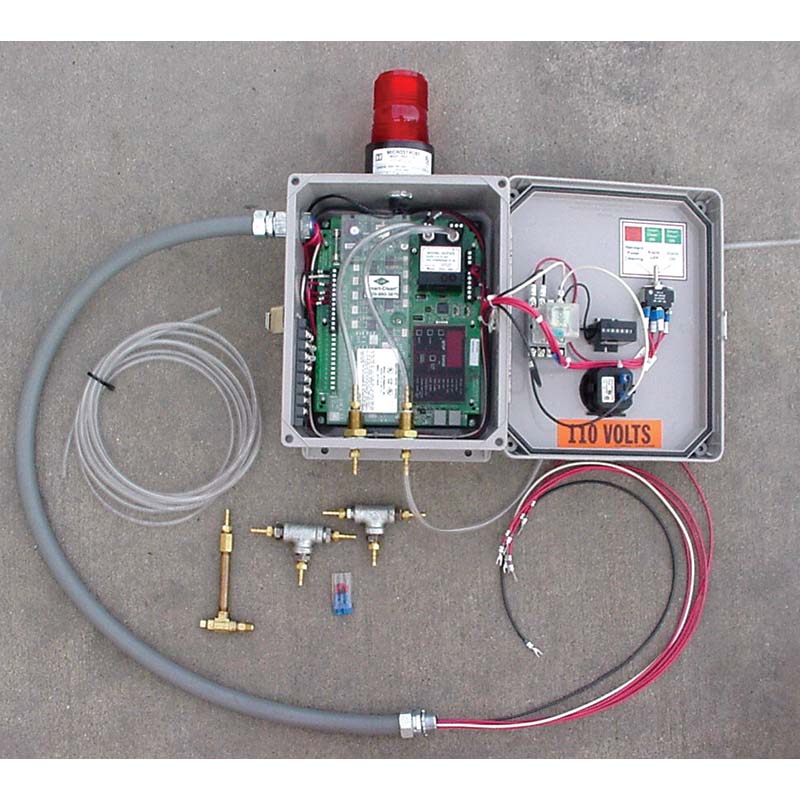

SILO SAVER SYSTEMS (ANTI-OVERFILL SYSTEM)

Silos and dust collectors are vital to production in the concrete industry, and are costly to replace or repair, when damaged. Silo Saver SystemsTM (SSSTM) were developed to minimize guessing and eliminate human error when dealing with the 3 majors threats to silo and dust collectors. The 3 major threats are:

High Pressure: When blowing materials INTO the silo (filling) high pressure can become a problem. Usually pressure above 1.5 PSI can cause damage to the silo.

Overfilling: Overfilling a silo can damage or destroy it.

Broken Filter Media: Can pollute the air and cause a producer to receive a citation.

Anti-Overfill: Existing bin indicator monitors material level and signals when silo is full. Overfill light and horn are activated and pinch valve shuts line down after a preset time, avoiding serious damage or injury.

Air Flow Switch: Senses air flow through the silo collector and automatically turns the cleaning system on. When air flow ceases, system automatically turns off.

Pressure Sensor: Pressure above 1.5 psi can damage your silo and dust collector. Pressure Sensor detects high pressure and shuts the material flow down. Pressure Switch can also send a signal to turn collector on/off.

Broken Media Filter: Broken filters create maintenance disasters and can cause citations to be issued. Broken filter sensor uses microwave technology to detect damages and possible dangerous situations.

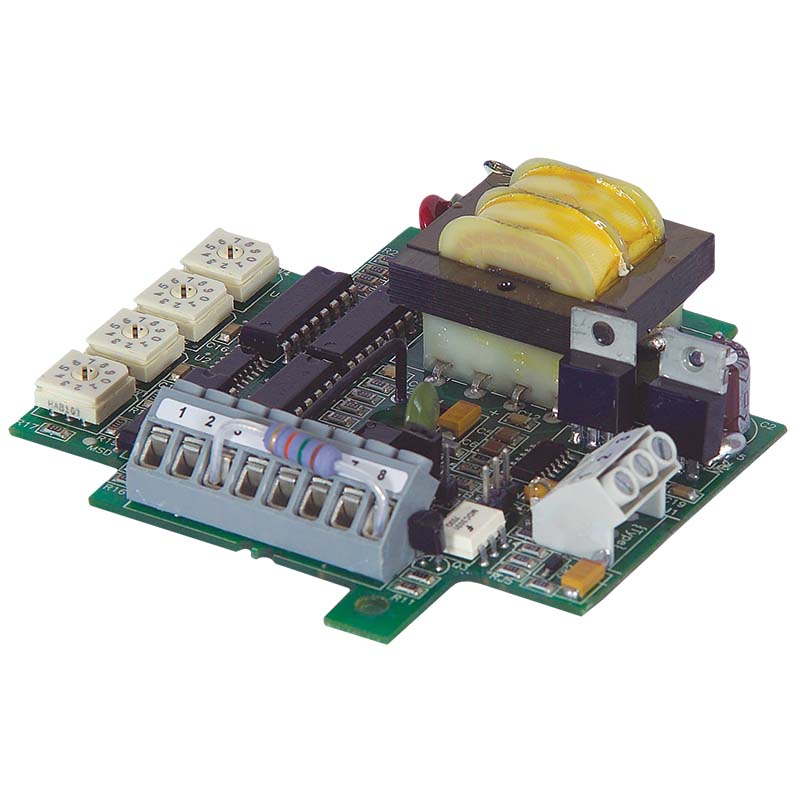

Smart-Clean: Is an automated cleaning system that manages when dust collector pulsing valves are activated (fired). Rather than pulsing on timed intervals, Smart-Clean increases the efficiency of the filtering by monitoring filter cake build up and keeping it within an optimal range. Key components include Smart-Clean Panel, Clean Out Connectors, and Pressure Hose.

ACCESSORIES

We offer accessories for your dust collectors

Aeration & Blowers • Air Line Control • Boots • Cement Screws & Loading Spouts • Concrete Plants • Conveyors • Dust Control System • Level Controls • Mixers • Valves & Cylinders • Vibrators • Water & Moisture Meters & Pumps • Wear Liners

C & G Equipment ● 3590 NW 96th Ave. ● Hollywood, FL 33024 ● Phone: (954) 602-1265 ● Fax: (954) 602-1275